Le parcours ambitieux vers la carboneutralité conduit à une demande accrue en systèmes énergétiques de quartier. Un grand nombre de municipalités et de campus mettent maintenant en place des solutions de chauffage et de refroidissement de quartier. Pour ce faire, l’on convertit d’anciennes installations énergivores à vapeur pour les transformer en réseaux durables d’eau chaude qui cadrent avec le passage général à des infrastructures plus écologiques.

Non seulement ces systèmes optimisent-ils l’utilisation de l’énergie, mais ils aident également beaucoup à la conservation de l’environnement. Poursuivez votre lecture pour découvrir ce que sont les systèmes énergétiques de quartier, leurs principaux composants, les avantages qu’ils offrent et comment commencer à mettre en œuvre un tel système.

Comprendre les systèmes énergétiques de quartier

Un système énergétique centralisé de quartier produit de l’énergie thermique et la fait circuler dans des tuyaux isolés qui sont reliés à plusieurs bâtiments au sein d’un quartier. Cette source d’énergie sert à réchauffer ou à refroidir l’eau et à climatiser le bâtiment connecté. Cette énergie est généralement produite à une centrale qui peut recourir elle-même à d’autres sources d’énergie comme le gaz naturel, la biomasse, la géothermie ou la chaleur résiduelle. L’on parle de système hydronique quand c’est de l’eau qui circule pour transmettre la chaleur. Dans un système énergétique de quartier, la centrale force l’eau chaude et glacée à circuler dans la tuyauterie.

Avantages du système énergétique de quartier et façon dont il aide à conserver l’environnement

Les systèmes énergétiques de quartier sont synonymes de simplicité et d’efficacité. En effet, le chauffage et le refroidissement étant fourni par réseau, plus besoin d’équipement pour les générer aux bâtiments mêmes. Et les propriétaires de ces bâtiments retirent des avantages qu’ils n’obtiendraient pas avec un équipement standard : une efficacité énergétique améliorée; une meilleure protection de l’environnement; le choix du carburant; une utilisation et un entretien facile; la fiabilité, le confort et la commodité; un plus grand cycle de vie qui réduit l’investissement, et la possibilité d’améliorer la conception architecturale grâce à l’espace libéré.

- Efficacité énergétique

En centralisant la production d’énergie, les systèmes énergétiques de quartier atteignent des niveaux d’efficacité plus élevés que les systèmes de bâtiment autonomes. Cette centralisation optimise l’utilisation des combustibles, réduit les pertes d’énergie et améliore la gestion de l’offre et de la demande en énergie. - Économies

Au fil du temps, l’efficacité des systèmes énergétiques de quartier se traduit par des économies pour les opérateurs et les utilisateurs. L’investissement initial dans un tel système peut s’avérer important, mais les économies opérationnelles à long terme et la réduction des factures d’énergie en font une option financièrement viable. - Conservation de l’environnement

Les systèmes énergétiques de quartier réduisent les émissions de gaz à effet de serre en utilisant l’énergie de manière plus efficace et en intégrant éventuellement des sources d’énergie renouvelables. Cela est d’autant plus important étant donné que les entreprises et les gouvernements s’efforcent d’atteindre des objectifs de réduction des émissions.

Réseau de tuyauterie pour le chauffage de quartier

Le réseau de tuyauterie qui distribue l’énergie thermique représente un élément essentiel de tout système énergétique de quartier. Le choix à l’égard d’un tel réseau a une incidence importante sur l’efficacité, la fiabilité et la rentabilité. Les systèmes énergétiques de quartier se composent généralement de tuyaux préisolés qui peuvent être rigides ou flexibles. Les systèmes modernes emploient souvent une combinaison des deux types de tuyaux. Les tuyaux flexibles s’installent en peu de temps et à peu de frais dans des tranchées étroites et peu profondes. Ils offrent ainsi un net avantage par rapport aux tuyaux rigides qui requièrent des tranchées plus profondes et larges. Dans les systèmes qui combinent les deux types de tuyaux, les tuyaux rigides servent d’ordinaire de conduites principales, tandis que les tuyaux flexibles s’utilisent comme conduites secondaires qui s’installent en un rien de temps.

Réseaux de tuyaux flexibles préisolés

Les réseaux de tuyaux flexibles sont tout indiqués pour le chauffage de quartier en raison de leur facilité d’installation et de leur adaptabilité à des environnements urbains complexes. Ces tuyaux permettent de contourner les obstacles, ce qui les rend idéaux pour la modernisation des zones urbaines établies. En outre, les tuyaux flexibles ont prouvé leur durabilité et leur résistance à la dilatation et à la contraction thermique, ce qui accroît la longévité du système.

Réseaux de tuyaux rigides

Bien que les tuyaux flexibles offrent de nombreux avantages, les réseaux de tuyaux rigides sont plus couramment utilisés, en particulier dans les grands projets ou lorsque de longs tronçons rectilignes de tuyauterie sont nécessaires. Ils assurent une excellente intégrité structurelle et sont généralement plus rentables sur le plan du coût des matériaux. Toutefois, leur installation nécessite une planification minutieuse et peut nécessiter une main-d’œuvre plus importante, en particulier dans les zones encombrées, ce qui se traduit par un coût d’installation global plus élevé.

Solutions de vannes et de tuyauterie Armour Valve pour les systèmes énergétiques de quartier

Les vannes contrôlent le flux d’énergie thermique dans les systèmes énergétiques de quartier, et leur fiabilité et efficacité sont primordiales pour la performance globale du système. Armour Valve propose plusieurs solutions pour les systèmes énergétiques de quartier, en ce qui concerne tant les vannes que la tuyauterie. Voici trois de nos principales gammes de produits ci-dessous.

La tuyauterie préisolée Brugg s’utilise pour les conduites principales de distribution du système. Elle réduit le temps d’installation et les perturbations, comme le montre cette étude de cas sur le raccordement d’un bâtiment municipal à un système de chauffage de quartier existant.

Boehmer propose des vannes à bille, notamment des vannes à bille préisolées, utilisées dans les réseaux d’eau chaude enterrés et soudées directement dans la canalisation lors de l’installation sur le site, ainsi que des vannes non isolées, utilisées pour les espaces d’entreposage, les conduites d’eau glacée, les points d’entrée des bâtiments et les stations de transfert d’énergie (STE), ainsi que dans les usines.

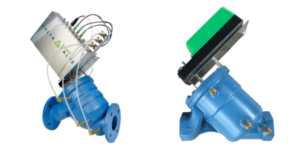

Les vannes de contrôle DeltaP de Flow Control Industries (FCI) servent aux échangeurs de chaleur et aux dispositifs de traitement de l’air dans l’ensemble du système pour maximiser l’efficacité des systèmes de chauffage, de ventilation et de climatisation (CVC) et réguler le système énergétique de quartier, en fournissant un contrôle précis de la température.

Tuyaux BRUGG

Tuyaux BRUGG

Brugg est un fabricant à service complet de réseaux de tuyauterie flexibles et rigides préisolés. Armour Valve distribue les produits uniques de Brugg sur le marché, notamment FLEXWELLMC, qui est le seul tuyau flexible pouvant être utilisé dans les applications de forage à direction horizontale.

Vanne à bille Boehmer pour l’énergie de quartier

Les vannes à bille s’utilisent pour l’isolation des réseaux d’eau chaude et glacée desservant un quartier. La vanne à bille Boehmer constitue un élément essentiel dans de nombreuses installations de chauffage de quartier et dans les réseaux de tuyauterie enterrés préisolés en raison de sa robustesse et de sa capacité à assurer une fermeture étanche, même dans des conditions de pression et de température élevées. Le matériau et la construction en acier forgé résistent aux forces de compression externes dans les applications enterrées. Il s’agit donc d’un choix idéal pour maintenir l’intégrité du système et assurer une fourniture d’énergie constante. Ces vannes à bille sont conçues pour durer, garantissant des années de fonctionnement sans corrosion et sans entretien.

Vannes DeltaP de FCI

La DeltaP de FCI est une autre vanne essentielle utilisée dans les systèmes de chauffage de quartier. FCI est l’inventrice de la vanne de contrôle indépendante de la pression (PIC), et la DeltaPValve a été la première vanne PIC sur le marché. Les vannes PIC servent à contrôler le débit d’eau dans les échangeurs de chaleur et les unités de traitement de l’air au sein du système de chauffage hydronique, de systèmes CVC d’un bâtiment. Aucune vanne d’équilibrage ni autre équipement n’est nécessaire, ce qui réduit les coûts d’installation et d’entretien.

Grâce à ses performances éprouvées et garanties en matière de contrôle de la pression différentielle, la vanne DeltaPValve contribue à maintenir l’équilibre du système, en évitant les pertes d’énergie et en veillant à ce que tous les bâtiments raccordés reçoivent un chauffage ou un refroidissement adéquat. Son utilisation dans les systèmes énergétiques de quartier s’avère particulièrement profitable dans les réseaux complexes où le maintien d’une pression uniforme est essentiel pour la stabilité du système et le contrôle constant de la température. Découvrez dans notre blogue comment la valve DeltaPValve a permis d’augmenter la capacité et de réaliser des économies d’énergie dans un centre médical d’urgence confronté à des problèmes de refroidisseurs.

La vanne DeltaP SmartValve de FCI complète la vanne DeltaPValve et la convertit en valve intelligente qui se connecte et fournit à la console centrale des rapports précis sur le système.

Démarrer avec les systèmes énergétiques de quartier

La mise en œuvre d’un système énergétique de quartier implique plusieurs étapes critiques qui garantissent que le système est conçu et exploité de manière efficace. Avant de se lancer dans la création d’un système énergétique de quartier, il est essentiel de réaliser une étude de faisabilité. Cette étude évalue le potentiel de mise en œuvre d’un tel système, en tenant compte de facteurs comme la demande d’énergie, les sources d’énergie disponibles et la viabilité économique.

Une fois la faisabilité établie, l’on passe à la conception et à l’ingénierie, qui comprennent une planification détaillée de l’aménagement du système, dont l’emplacement de la centrale, du réseau de tuyauterie et de l’infrastructure connexe. Le choix des réseaux de tuyauterie et des vannes appropriés représente une étape décisive pour s’assurer que le système répond aux besoins particuliers d’un quartier.

En outre, un système énergétique de quartier doit se conformer à diverses exigences réglementaires, notamment à des normes environnementales et à des règles de sécurité. Il est essentiel d’interagir avec les organismes de réglementation dès le début du processus de planification afin de s’assurer que la conception du système répond à tous les critères nécessaires, de sorte à éviter les retards au cours de la construction.

Comment Armour Valve peut répondre à vos besoins en matière d’énergie de quartier

Les systèmes énergétiques de quartier constituent une solution efficace pour assurer le chauffage et le refroidissement tout en réduisant les coûts énergétiques, en améliorant l’efficacité et en réduisant au minimum l’incidence sur l’environnement. En comprenant les éléments et les étapes clés de la mise en œuvre d’un système énergétique de quartier, les organisations et les municipalités peuvent en retirer tous les avantages.

Si vous envisagez d’installer un système énergétique de quartier au sein de votre communauté ou de votre organisation, fixez un rendez-vous de consultation avec notre responsable du marché de l’énergie de quartier en vue d’explorer nos solutions dans le domaine et de discuter de vos besoins particuliers.