Issue & Importance

A steel plant installed two new boilers and a cogeneration facility for redundancy within their system. The boilers were designed to run on natural gas, as well as a blend of coke oven gas, blast furnace gas, and natural gas. When plant personnel needed to repair the system or run on natural gas alone, they had to isolate the coke oven and blast furnace gas lines. This required them to use a crane, unbolt the flanges, and install a large piping blind. The entire process took two days to complete, resulting in significant lost production and revenue.

Solution

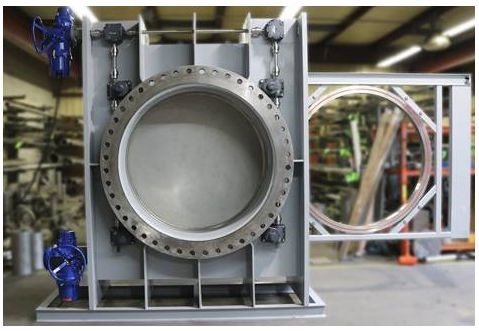

Two 48” Goggle valves were engineered for the steel plant after a consultation with Armour Valve and our manufacturing partner SchuF. The solution provided a double block and bleed effect required for their blast furnace system and was designed so that it could be remotely operated from a safe distance. The first actuator unlocks the unit and the second one cycles the blanking plate. This reduced downtime from two days to just one minute of delay. Unlike traditional line blinding solutions, SchuF’s Goggle valves require no spreading of piping. One person can typically operate the Goggle valve without the need of special tools or equipment.

An Automated 48” Goggle Valve

Impact

On a daily basis, the steel plant has to throttle down the boilers in-between heats; which requires switching to straight natural gas while the unit is throttling down. As the system is throttling up, operators need to reopen the units for full flow. Maintenance personnel can then isolate the line without having to unbolt flanges to install a large piping blind with the assistance of a crane, saving valuable time and resources.

Not only are the automated SchuF Goggle valves simple to operate; they allow the plant to gain an extra heat per day, which increases their daily output by 500 metric tons of steel. This output equates to $1.65M in extra revenue per day based on 2022 prices of $1.50 per pound. The steel plant was able to recoup all valve and installation costs as of the first extra heat performed.