Armour Valve’s supplier, Flow Control Industries, Inc. (FCI), is a specialty manufacturer of high-performance Pressure Independent Control Valves (PICVs), delivering energy-efficient products and services that increase building value and lower total cost of ownership (TCO). FCI is a leading player in the market when it comes to addressing delta T, energy, and capacity concerns and providing precision control solutions.

Armour Valve’s supplier, Flow Control Industries, Inc. (FCI), is a specialty manufacturer of high-performance Pressure Independent Control Valves (PICVs), delivering energy-efficient products and services that increase building value and lower total cost of ownership (TCO). FCI is a leading player in the market when it comes to addressing delta T, energy, and capacity concerns and providing precision control solutions.

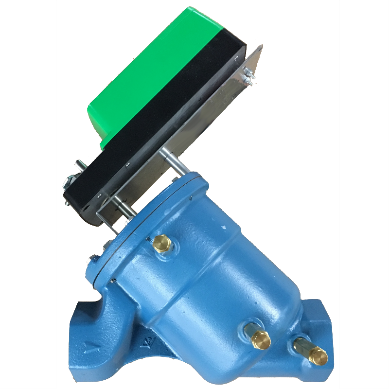

The DeltaPValve®, manufactured by FCI, was the first Pressure Independent Control Valve for HVAC systems. Used in projects around the world, the DeltaPValve® is consistently saving customers millions of dollars in first costs, operating costs, and deferred capital costs.

The DeltaPValve®, manufactured by FCI, was the first Pressure Independent Control Valve for HVAC systems. Used in projects around the world, the DeltaPValve® is consistently saving customers millions of dollars in first costs, operating costs, and deferred capital costs.

The DeltaPValve® is utilized for retrofits in hydronic district energy systems to improve efficiency and performance while reducing costs. A District Energy System is also referred to as a low-carbon thermal energy network. These systems produce hot water, steam, and chilled water, which is used as thermal energy that is then distributed to a group of buildings. These systems are typically used in hospitals, college campuses, and military bases, among other applications. The video below provides an overview of District Energy Systems.

Video produced by the International District Energy Association

Issue

A Trauma 1 Emergency Medical Center in California was experiencing poor performance and limited distribution flow on their CHP chilled water system. This was partially due to low delta T building performance that required excessive pumping energy and the use of building chillers to address cooling demand. The Emergency Medical Center lost 50% of capacity on its chillers and was concerned about running out of capacity. Its 26 MW cogeneration plant serves 16 buildings with critical areas, which makes capacity, performance, and energy consumption improvements especially important.

Solution

The Medical Center installed DeltaPValve® in all campus buildings in order to improve delta T returns and increase the efficiency of their cogeneration plant. This was part of a retrofit performance upgrade and included other actions that were taken to improve the systems involved:

- Installing chilled water return temperature sensors for each cooling coil to monitor the performance of the cooling coils.

- Tuning of the existing control valve algorithms to reflect Pl control.

- Calibration of all discharge air temperature sensors to allow for accurate process variable feedback to the system controller.

- Revisions to the distribution system pump VFD control allowed for control from the hydraulically most remote point in the distribution system, which eliminated the low flow issues.

Results

The DeltaPValve® improved the chilled and heating water system delta T performances and significantly increased available capacity and energy savings.

The Emergency Medical Center is now able to operate with higher efficiencies while maintaining the same level of capacity and comfort while using less equipment.

Other results included:

- A rise in chilled water distribution system delta T from 8-9°F (4.4-5°C) to 15°F (8.4°C) just prior to the decoupler at the CHP.

- The CHP chilled water system now stages machines in response to load and not flow.

- Distribution system pumping energy requirements have been cut by 50%.

The chilled water system operation during 114°F (45.6°C) heat, which was in excess of design conditions, required only one of two 750 Hp distribution pumps as compared to 8-9°F (4.4-5°C) operation at less than design conditions requiring two 750 Hp distribution pumps.

FCI & Engineered Hydronic System Efficiency

FCI has extensive experience with hydronic systems and has identified the characteristics that make them efficient, including:

- The ability to maintain the coil leaving air temperature (LAT) at +/-0.1°F.

- The coil is designed to chill and heat water ΔT at or above the specified design level under all load conditions.

- The hydronic system is dynamically balanced to ensure stability at all load conditions.

- The system is designed to provide diversity and effective pump control, ensuring reliable performance.

As a result, the DeltaPValve® is designed with the following characteristics to ensure efficiency:

- The ability to maintain ± 0.1° coil leaving air temperature.

- Valves are factory calibrated and tested to ensure full shutoff and pressure independent performance.

- Pressure Independent Control stabilizes the system and improves efficiency by removing flow variations caused by pressure fluctuations.

- The DeltaPValve® is the only variable flow hydronic system that guarantees ΔT, which is the best indicator of demand-side system efficiency.

- An industrial quality, field-serviceable, debris-resistant design with stainless steel and brass internal components that allow for a 30+ year life cycle.

- Field-verifiable performance using inlet, intermediate, and outlet P/T ports.

- 100:1 turndown and the ability to control flow throughout the full range of the control valve.

- Full system compatibility with flow ranges of 0.5-5500 GPM for precision control throughout the whole system.

More on the DeltaPValve®

Conventional pressure-dependent control valves cause a change in flow whenever there is an increase in pressure, no matter the position. Increasing inlet pressure also increases the flow rate, and it remains elevated until the building automation identifies the issue and responds to adjust the flow rate.

When you have multiple control valves in a system, each of these adjustments affects the other control valves and creates unstable flow and poor performance. When using the pressure independent DeltaPValve®, pressure variations will not affect the flow rate at any valve position. Increases in inlet pressure trigger an immediate response from the mechanical pressure regulator so that the outlet flow rate remains constant.

DeltaPValve® systems eliminate pressure variability and match the exact flow required for any set of conditions. These valves streamline valve selection, simplify the building automation system controls, and expand the capabilities of other equipment. The video below from FCI provides an overview of the DeltaPValve® and its operation.

Video produced by FCI: flowcontrol.com

Other DeltaPValve® Benefits:

- Guaranteed to meet or exceed design ΔT performance and increase efficiency.

- Reduced energy costs through increased system stability.

- Lower installation, operation, and lifecycle costs.

- DeltaPValve® is industrial quality and designed to last the life of the facility.

- Saves 25-50% of chilled water energy.

- Reduced maintenance due to self-balancing capabilities.

- Improved comfort due to precise response and stabilization of leaving air temperature.

- Enables system capacity recovery to utilize the full, installed system capacity.

- All 1⁄2” – 8” valves are covered by a 10-year warranty.

Armour Valve is a Canadian Distributor of FCI Products

Armour Valve is proud to distribute Flow Control Industries products in Canada. You can contact us to purchase the Flow Control Industries DeltaPValve (PICV) in 1/2″ to 16″ sizes. Additionally, a system optimization consultation is available upon request from Armour Valve. We also carry other solutions for district heating and would be happy to discuss valve options with you. Browse our catalogue on our website to learn more about the solutions we offer.