The quest for sustainable energy solutions has led to innovative approaches to reducing greenhouse gas (GHG) emissions. One such approach is hydrogen blending, a process that mixes hydrogen with natural gas to create a cleaner fuel source. This post explores the benefits of hydrogen blending, its role in GHG reduction, and why Boehmer ball valves are at the forefront of this energy revolution.

What is Hydrogen Blending?

Hydrogen blending is a pathway to reducing greenhouse gas (GHG) emissions and delivering cleaner energy that is actively being pursued worldwide. Hydrogen, when burned, releases water vapour instead of carbon dioxide, making it a clean energy source. The blending process allows for a gradual transition from fossil fuels to renewable energy sources, providing a scalable pathway to decarbonize our energy systems.

Hydrogen blending allows for varied concentration levels – usually 20% or less – of hydrogen by volume through existing natural gas pipeline systems. This is a practical solution to the often limited or inconsistent supply of hydrogen, facilitating a steady and adaptable transition towards cleaner energy. This approach’s flexibility is crucial, allowing for gradual integration into existing systems and infrastructure, with adjustments made as needed to align with technical, economic, and safety considerations.

Boehmer GmbH: Two Decades of Hydrogen Expertise

With more than 20 years of experience in hydrogen applications, Boehmer GmbH has established itself as a leader in ball valve technology. Boehmer’s expertise is evident in its involvement in landmark projects like the ATCO Fort Saskatchewan Hydrogen Blending project in Alberta, Canada. This initiative made Alberta the first province in Canada to use hydrogen-blended natural gas to fuel homes and businesses for 2,100 customers. The project involved blending natural gas with five percent hydrogen by volume to reduce greenhouse gas emissions, demonstrating the viability of hydrogen as a cleaner energy source. Boehmer GmbH was instrumental in this project, supplying the specialized valves needed to handle the unique properties of hydrogen.

Boehmer’s valves are engineered to meet the unique demands of hydrogen applications. The materials used are of the highest purity, avoiding cast or plate materials that could trap hydrogen atoms and lead to embrittlement. Boehmer’s design calculations account for high-pressure environments and the low pressures typical of hydrogen use, ensuring reliability and safety.

Boehmer’s valves are engineered to meet the unique demands of hydrogen applications. The materials used are of the highest purity, avoiding cast or plate materials that could trap hydrogen atoms and lead to embrittlement. Boehmer’s design calculations account for high-pressure environments and the low pressures typical of hydrogen use, ensuring reliability and safety.

Armour Valve: Your Exclusive Canadian Supplier of Boehmer Gas Valves

As Boehmer’s exclusive representative and stocking distributor for gas ball valves in Canada, Armour Valve is your trusted partner for accessing Boehmer’s cutting-edge valve solutions. Armour Valve’s commitment to quality and service ensures that customers receive the best products tailored to their hydrogen blending projects.

Why Boehmer Valves Are the Ideal Choice For Hydrogen Blending

- Material Integrity: Boehmer valves are designed with the purest materials to prevent hydrogen embrittlement, ensuring long-term durability and safety.

- Design Excellence: The valves are calculated for optimal wall thickness to withstand various pressures, crucial for both high-pressure and low-pressure hydrogen applications.

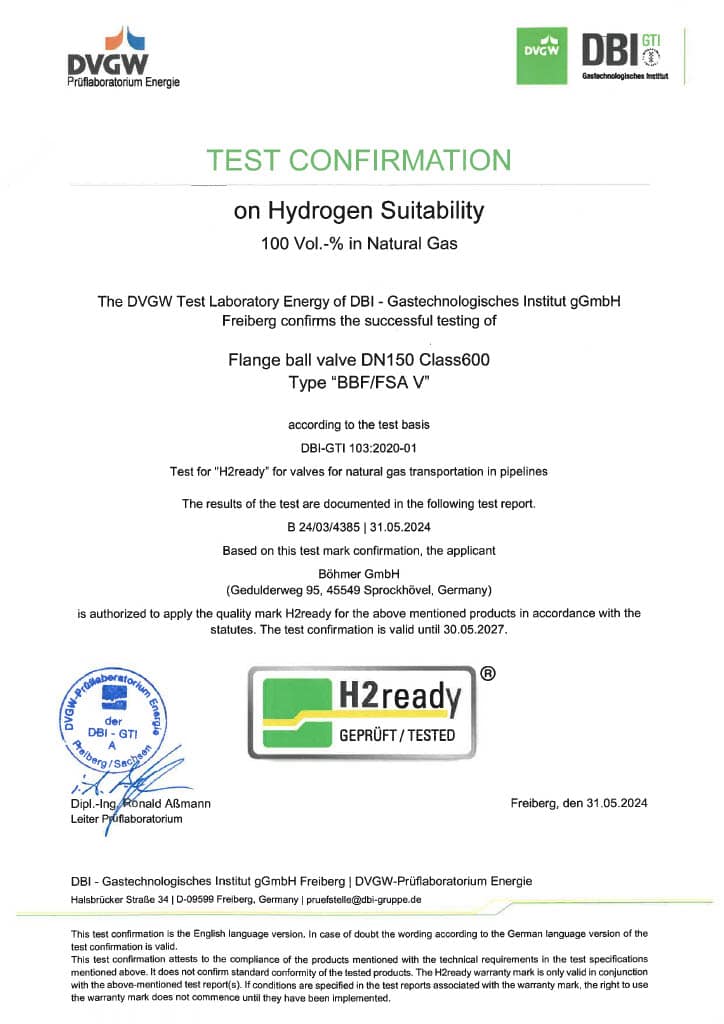

- Certification and Standards: Boehmer is setting the standard in the development of standards for hydrogen valves, with products undergoing rigorous testing to ensure they can handle 100% hydrogen safely.

- Innovative Construction: The Boehmer Fully Welded Ball Valve offers enhanced strength and eliminates potential leak paths, crucial for maintaining the integrity of hydrogen systems.

- Quality Assurance: Boehmer’s stem assembly is tested to ISO fugitive emissions standards, with certifications that guarantee performance even after 50,000 cycles, tested with helium for utmost reliability.

Boehmer Ball Valves Set the Standard for Hydrogen Testing

While the optimal percentage of hydrogen blending is still under research, Boehmer’s valves have been used in Germany with 100% hydrogen, indicating the potential for high blending percentages.

While the optimal percentage of hydrogen blending is still under research, Boehmer’s valves have been used in Germany with 100% hydrogen, indicating the potential for high blending percentages.

Boehmer has diligently tested its gas ball valves to determine their effectiveness for use in applications involving 100% hydrogen, including embrittlement and permeation testing. Boehmer is renowned for its high-standard ball valves designed for demanding conditions, capable of handling various media up to DN1400 / 56” size and pressures up to 500 bar. Boehmer valves not only meet but exceed market standards thanks to a team of skilled engineers and designers who focus on quality and durability in their designs.

Boehmer is also involved in the development of Annex M of API6D, a committee that is setting specific standards for constructing ball valves for hydrogen. Additionally, Boehmer recently partnered with a German third-party Technical Inspection Association called TÜV SÜD to develop a testing procedure for valves on hydrogen. This procedure tests valves with 100% hydrogen, including pressure and operations testing. Boehmer is the first ball valve manufacturer in the world to receive a signed TÜV report confirming performance in a test that subjected a 24 inch class 600 valve for transmission with 100 actuation cycles and 1,250 pressure cycles with 100% Hydrogen (H2).

Hydrogen blending represents a significant step towards a cleaner energy future, and Boehmer’s valves are at the heart of this transition. As an exclusive supplier of Boehmer gas valves in Canada, Armour Valve can offer our customers leading hydrogen valve technology and help pave the path towards reducing GHG emissions through hydrogen blending. As the industry advances, we look forward to collaborating with Boehmer to bring more solutions to our customers and help in shaping a sustainable energy landscape.