Steam systems are essential in many industries, from papermaking to district energy. However, like any system, they are not immune to issues that can lead to inefficiencies, downtime, and even damage. Having the right valves and process equipment in place to ensure that your steam system or Pressure Reducing and Desuperheating System (PRDS) works properly is essential for the lifespan of your equipment.

The Armour Valve team has identified a common issue with manual temperature control valve isolators in steam systems that can cause long-term damage. Keep reading to learn more about the simple solution that will solve this issue and help extend the life of your equipment and improve efficiency.

The Problem with Current Steam Conditioning Systems

In cogeneration facilities, steam conditioning valves play a pivotal role, they duplicate the conditions of what normally is provided by the extraction steam at specific points within a turbine. The steam conditioning valves adjust it to the desired pressure and temperature for various processes. One of the primary applications of these valves is a turbine bypass. These valves ensure that even when the turbine is down, steam remains available for essential processes.

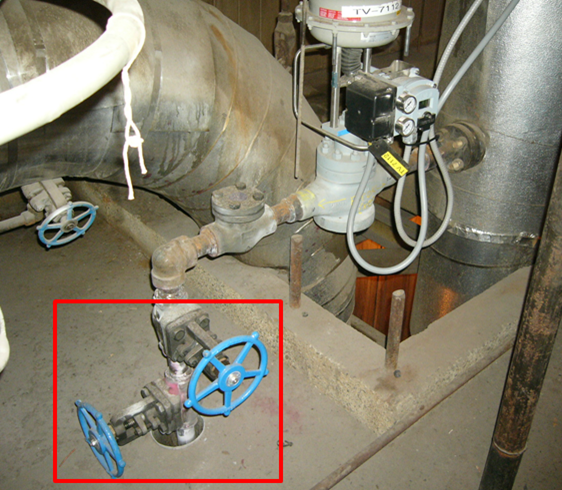

A recurring issue has been identified in many of these systems. In certain systems with turbines, the temperature control valves (TCV) are used to supply cooling water to the desuperheaters or steam conditioning valves. Manual isolators for the temperature control valves are commonly maintained in an open position, and the TCV is normally closed and in a standby state, ensuring rapid responsiveness, and minimizing downtime in the event of a turbine shutdown.

However, temperature control valves are not meant to be used as isolation valves. Leaving these valves in a closed position compromises the isolation of the steam conditioning valve, allowing high-pressure water to infiltrate the steam system. Prolonged misuse of the valve in this way can result in potential leaks and consequential damage. The accumulation of water, followed by the introduction of hot steam, can cause problems like water hammer, which can shake the system and even cause damage to structural components.

Actuated Conval Ball Valve

Armour Valve’s Solution

The solution, as proposed by Armour Valve, is both straightforward and effective. It involves introducing an actuated isolation valve to the system. An actuator can be added to the necessary isolation valve and can be controlled remotely, allowing for rapid adjustments when necessary. This addition will ensure you don’t have to use the TCV as an isolation valve and prevent water from accumulating, thereby extending the life of the equipment involved and averting potential system damage.

The advantages of implementing this solution are manifold:

-

- Extended Equipment Life: By preventing water accumulation, the life of the temperature control valve and the steam conditioning valve is significantly extended.

- Reduced Downtime: By preventing water accumulation, the chances of downtime due to damage or inefficiencies are greatly reduced.

- Cost Savings: Preventing potential damage means avoiding costly repairs or replacements.

- Improved Efficiency: A system that operates as intended without the risk of water hammer or internal damage is naturally more efficient and reliable.

Choosing the Right Valve

When it comes to selecting the right valve for this application, there are several options available. High-pressure systems commonly use globe, gate, or ball valves. However, for this specific application, ball valves are highly recommended due to their efficiency and user-friendly nature. Armour Valve can also provide actuated temperature control valves and steam conditioning valves as a unit.

Actuated Temperature Control Valves and Steam Conditioning Valves

Conval Camseal Ball Valve

Conval Camseal Ball Valve

While there are many brands available, we at Armour Valve highly recommend Conval valves. Conval Camseal ball valves are designed for the world’s most demanding high-pressure, high-temperature applications, the Camseal is typically used for high-pressure and/or temperature ON/OFF isolation.

The Camseal is a quarter-turn, metal-seated cartridge-style top-entry ball valve. The internals are designed as a cartridge that can easily be removed and renewed in-line. This design provides considerable savings on repair and maintenance times versus the competition. Like all of Conval’s products, the Camseal is manufactured in Enfield Connecticut and meticulously tested every step of the way. The Camseal is certified to several global QA standards, including ASME, ISO 9001, PED, API, IBR, and more.

HORA Temperature Control Valves & Steam Conditioning Valves

The fundamental principle of a steam conditioning system is a steam reduction valve to reduce the steam pressure, a downstream or integrated cooler to reduce the temperature, an injection control valve or TCV to regulate the steam temperature and, if applicable, the related shut-off valves and corresponding actuator technology.

Hora Steam Conditioning Valve

HORA provides customized flow control solutions for the energy-focused market sectors and offers a comprehensive portfolio of standard and heavy-duty control valve solutions. HORA develops, engineers, and manufactures all its core products in Germany to guarantee product quality. HORA valves control gas, steam, and liquid flows in all areas of industrial applications. They are specially designed for water and steam at high pressures and temperatures.

HORA provides modular high-pressure and low-pressure temperature control valves both for standard and special constructions for power plants and industrial systems. These are applied in pressure and flow reduction applications. The TCV is used to control the amount of cooling water required for the Steam conditioning valve.

HORA offers steam conditioning valves, also called PRDS (pressure reducing and desuperheating) valves, in a range of configurations to meet the specific process conditions of the customer. A CFD (computational fluid dynamics) analysis is used to provide an optimum cost-effective solution to the customer. HORA also has high-pressure, medium-pressure, and low-pressure solutions for turbine bypass in steam conditioning applications.

Armour Valve Can Assist You with Choosing the Correct Valves for Your System

Awareness is the first step towards improvement. Many industries are unaware of this simple actuated ball valve solution that can prevent significant issues in their steam systems. By educating end users and industry players about the importance of isolation valves, we can pave the way for more efficient systems, reduced downtime, and substantial cost savings.

This simple system adjustment can save a lot in the long run. By adding an actuated isolation valve, industries can ensure the longevity of their systems and prevent potential damage.

For those interested in learning more or seeking expert advice, the team at Armour Valve is always available to assist. Contact us for more information on our tailored solutions for your steam systems.