The marine shipping industry is crucial for global trade, transporting commodities and resources across the world. With the industry experiencing growth, there is a higher demand for top-quality equipment and solutions that guarantee efficient and secure operations. Among the crucial components in marine shipping are valves that control the flow of liquids and gases in various systems. At Armour Valve, we take pride in supporting the marine industry by providing a range of valve solutions that cater to the unique demands of marine environments. Our marine shipping catalog includes Somas triple offset butterfly valves and exhaust gas recirculation valves; SchuF Line blinds and sampling valves, and Fossil magnetic level indicators.

Marine Shipping Solutions

To meet the unique challenges of the marine environment, valves designed for the marine shipping industry require solutions that ensure reliable and safe operations while addressing issues such as corrosion, limited accessibility and tight spaces. Utilizing corrosion-resistant materials such as stainless steel or epoxy coatings can help protect valves from corrosive substances like seawater. Additionally, the development of compact and lightweight valve designs that are easy to install and maintain in tight spaces is important. Moreover, the adoption of smart valve technologies, like remote monitoring and control systems, can provide real-time information on valve performance and enable proactive maintenance and repairs. Taken together, these measures ensure safe and efficient marine operations, reducing downtime and maintenance costs while enhancing reliability and safety.

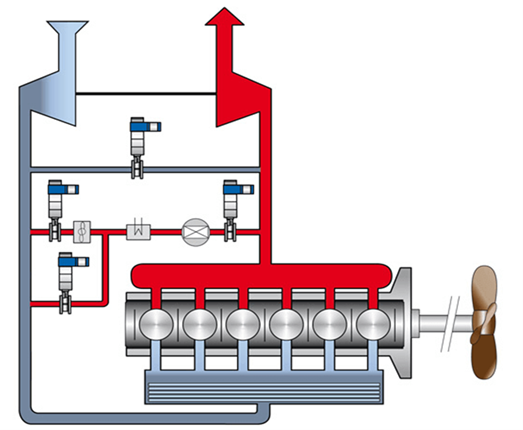

Exhaust Gas Recirculation Valves

Ships are a significant source of emissions, particularly of harmful pollutants like nitrogen oxides (NOx) and sulfur oxides (SOx). Exhaust Gas Recirculation (EGR) valves play a critical role in reducing emissions from ships. By recirculating a portion of the engine’s exhaust gas back into the engine’s intake air system, the EGR valve reduces the formation of harmful NOx emissions. Additionally, by using low-sulfur fuels in conjunction with EGR technology, ships can significantly reduce their overall emissions, helping to protect the environment and meet regulatory requirements. EGR valves are an essential component in the shipping industry’s efforts to reduce emissions and improve sustainability.

Somas provides valve solutions for waste gate applications and exhaust gas recovery. Specifically designed to be service-friendly, Somas EGR valves enhance fuel efficiency for marine vessels by providing accurate gas control and a tight shut-off mechanism, thanks to their innovative valve shaft and adaptable metal seat design. These valves can also be used to redirect exhaust so it can be used to heat the boat or any processes that may require heat. They redirect the exhaust through a heat exchanger, which then heats water or glycol that is then re-distributed through the vessel.

The Somas EGR valve has a metal seat capable of withstanding high temperatures and soot particles while providing tight shut-off and reducing harmful emissions. Its advanced triple eccentric design also minimizes sealing surface wear, ensuring the valve operates at peak performance for longer.

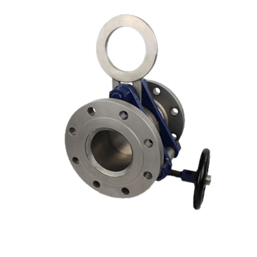

Triple Offset Butterfly Valves

The Somas Triple Offset Butterfly valve is a great solution for cargo storage transfers thanks to its reduced weight and unique disc and seat design that allows for field repair. The design also guarantees secure shut-off for leak-free operation. Additionally, Somas TOVs are designed to be low maintenance, which helps to reduce downtime and maintenance costs.

The advanced triple eccentric design of these valves is equipped with a distinct disc shape, which facilitates the usage of solid stainless steel seats, and reduces wear and tear. The first eccentricity relocates the sealing line away from the valve’s centerline, resulting in an uninterrupted sealing line. The second and third eccentricities, along with the conical shape of the disc, guarantee precise seating and a focal point that reduces deterioration.

Our marine shipping customer like the durability and ease of repair of Somas valves. Somas valves have fewer maintenance issues and are nearly maintenance-free. The Triple Offset Butterfly Valves are designed to be repaired instead of replaced, which helps to reduce the time spent being offline for repairs alongside associated costs.

SchuF Line Blinds

Although traditional methods for blinding pipelines, such as using metal plates with gaskets between flanges, ensure safety, they can be cumbersome to operate. Opening or closing them requires significant time and effort, particularly for larger size blinds, which may necessitate the involvement of multiple personnel or expensive equipment like cranes.

Advanced line blind systems like the SchuF Fetterolf Cam-Set® or Cam-Slide® have revolutionized the blinding process by enabling a single person to complete the installation within minutes, guaranteeing downstream safety. Line Blinds are also a great way to isolate the on-loading and off-loading system for liquid cargos such as fuels & oils. The line blinds reduce the requirement of bolting and unbolting of flange blanks to the inlets and outlets of the loading/off-loading system. This reduces time and the requirement of maintenance crew to operate while increasing the prevention of any leaking or spillage.

SchuF Line Blinds are engineered with an internal cam system that eliminates the need to spread the body flanges or move the adjacent piping when changing the spectacle plate. They have proven successful in assuring downstream safety for many of our customers in addition to the reducing maintenance time.

Schuf Sampling Valves

SchuF Sampling valves are designed to be dead space free and non-clogging, ensuring that there is no room for media to get jammed. This unique design allows for efficient product sampling from tanks offering both low maintenance and long life. Sampling valves can also be used to drain tanks or pipelines within the vessel. These valves are available in a variety of sealing types and in a wide range of vessel connection and accessory options, providing a customizable solution to suit various application needs.

Quality Solutions: Armour Valve’s Unwavering Commitment

Armour Valve provides comprehensive support to marine shipping customers, offering stocked, sourced, and engineered solutions. Our product range also includes brass and metric valves, as well as pressure relief valves for compressors. With over 100 quality-approved suppliers, we can assist you in sourcing your requirements or develop custom solutions that meet your specific application needs. Contact us today to schedule a personalized product consultation.