Globe Valve Basics: What They Are, How They Work, and When to Use Them

Globe valves are one of the most common—and most trusted—valve types in industrial flow control, and it’s easy to see why. Their ability to regulate flow with precision makes them a go‑to choice anywhere accuracy, reliability, and repeatability matters.

Whether you’re designing a system, troubleshooting performance issues, or comparing options for a new project, having a solid grasp of how globe valves work will help you make smarter decisions. This guide walks you through the basics: how they operate, where they’re used, and what to look for when selecting the right globe valve for your application.

Globe Valve Basics: What Is a Globe Valve?

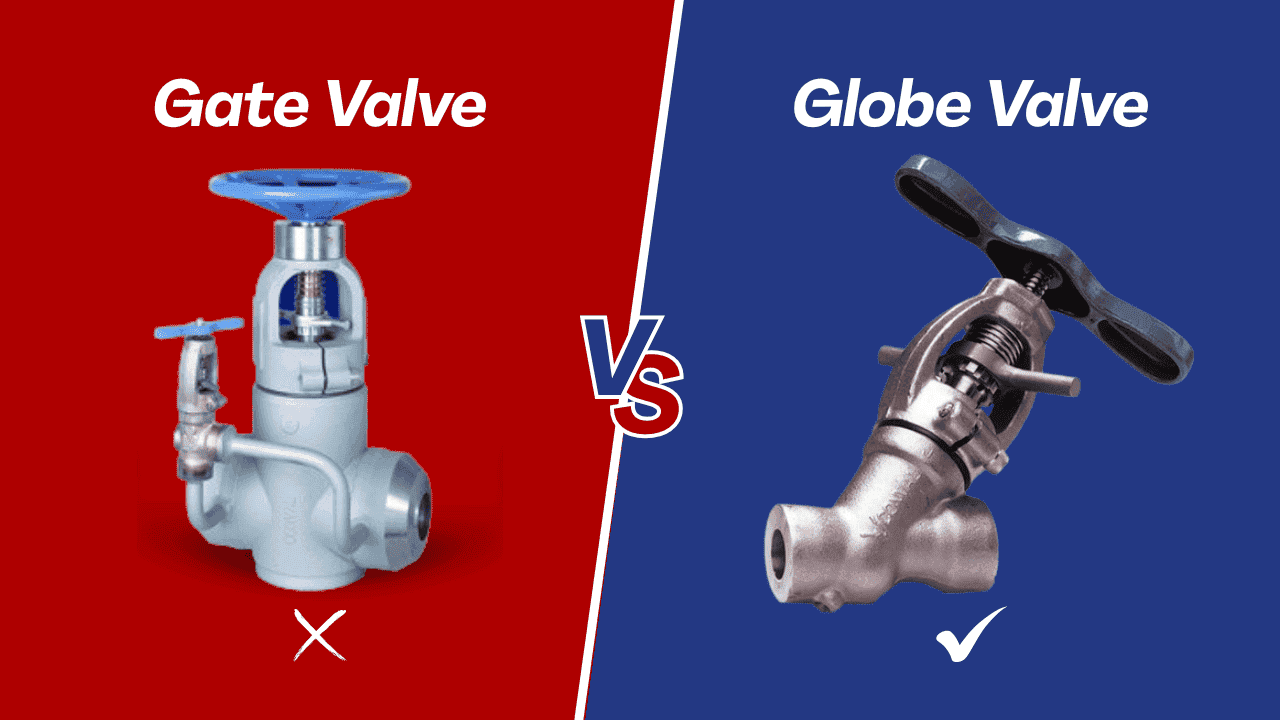

A globe valve is a linear‑motion valve designed to start, stop, and regulate flow. Unlike gate valves—which are mainly used for simple on‑off isolation—globe valves shine in applications where you need real control over how much flow passes through the system. While a globe valve can be used for isolation, its geometry is really built for regulating flow in a partially open position. Gate valves, on the other hand, are meant to be either fully open or fully closed.

If you’re choosing a globe valve for on‑off service, it’s worth keeping shutoff performance in mind. Tight shutoff can be harder to achieve when system pressure pushes upward on the disc. However, when flow enters from above the disc, the fluid force helps the disc seal more effectively, making a tight shutoff easier to achieve.

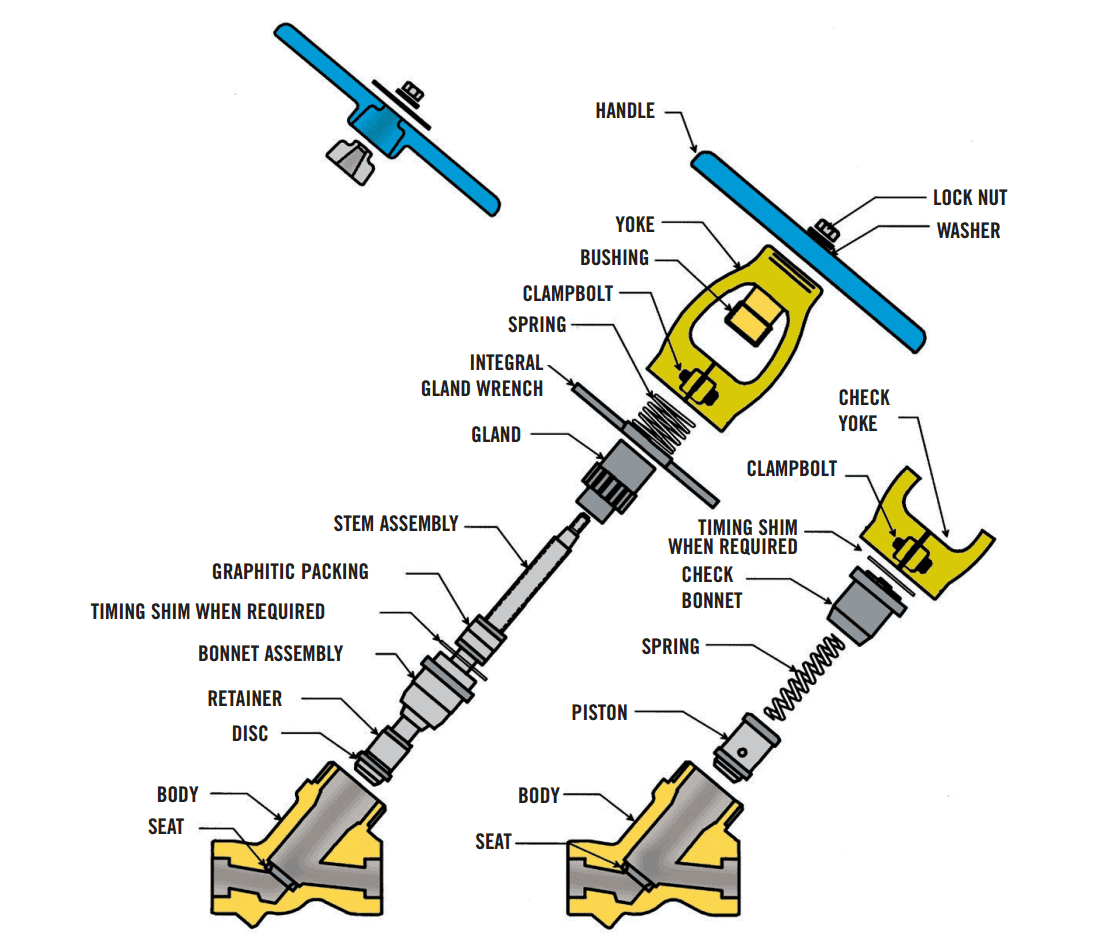

Components of a Typical Globe Valve

A globe valve is made up of several key components that work together to regulate flow, provide shutoff, and withstand demanding operating conditions. Understanding each part helps maintenance teams diagnose issues and select the right valve for their application.

Body

The body is the main pressure‑containing structure of the valve. It’s typically spherical or oblong, which is where the term “globe valve” originates. The body houses the internal flow path, including the seat and disc, and is designed to withstand system pressure, temperature, and mechanical stresses. Body geometry varies by pattern (T‑pattern, Y‑pattern, Angle pattern), each offering different flow characteristics and pressure drop profiles.

Bonnet

In conventional globe valves, the bonnet encloses the upper portion of the valve and provides a pressure‑tight seal around the stem. It contains the packing system, guides the stem’s movement, and connects to the body using bolted, threaded, or pressure‑seal designs. In Conval’s Clampseal design, however, the term “bonnet” refers to a removable pressure‑seal cartridge assembly that houses the stem and packing while allowing rapid access to the trim for inspection or maintenance. In high‑pressure or high‑temperature service, pressure‑seal bonnets are often used to improve sealing performance and reduce maintenance requirements.

Stem

The stem is a precision‑machined shaft that transfers motion from the handwheel or actuator to the disc. As the stem moves up or down, it positions the disc relative to the seat to control flow. Stems must resist bending, galling, and wear, especially in high‑cycle or high‑temperature applications. Proper stem alignment is critical for smooth operation and tight shutoff.

Disc (or Plug)

The disc is the primary flow‑controlling element. It moves perpendicular to the seat to throttle or stop flow. Different disc designs — such as plug, composition, or needle — offer varying levels of control accuracy and durability. In severe service, many manufacturers rely on hardened or coated discs to fight erosion, cavitation, and corrosion. Conval however goes further, using Stellite (hard material) for significantly greater durability.

Seat

The seat provides the sealing surface against which the disc closes. It may be integral to the body or a separate, replaceable component. Seat geometry and material selection directly influence shutoff performance, wear resistance, and valve longevity. A well‑maintained seat is essential for preventing leakage and maintaining control accuracy.

Actuator or Handwheel

The actuator or handwheel provides the force needed to move the stem and disc. Handwheels are used for manual operation and are common in general service. Actuators (electric, pneumatic, or hydraulic) are used when precise control, remote operation, or high cycling is required.

How a Globe Valve Works

Globe valves regulate flow using a linear motion mechanism: the disc (or plug) moves vertically, lifting off the seat to allow fluid to pass or pressing onto the seat to restrict it. This perpendicular movement allows for precise modulation of flow, making globe valves ideal for throttling applications.

Globe valves regulate flow using a linear motion mechanism: the disc (or plug) moves vertically, lifting off the seat to allow fluid to pass or pressing onto the seat to restrict it. This perpendicular movement allows for precise modulation of flow, making globe valves ideal for throttling applications.

Understanding the Flow Path

The internal geometry of a globe valve forces the fluid to change direction twice—first moving under the seat as it enters, then over the seat as it exits toward the outlet. This creates an “S‑shaped” flow path that has several important implications:

Accurate Throttling: The disc’s position directly affects the flow area, allowing fine control over flow rate. This makes globe valves suited for modulating service. Although globe valves can be used for modulating service, we typically recommend dedicated throttling valves for power plant applications. Their design offers better control stability, reduced wear, and improved performance under demanding conditions. Learn why this distinction matters → Read the full article

Improved Shutoff: The disc presses firmly against the seat to create a reliable seal when closed — especially when flow enters over the seat, where fluid pressure helps reinforce the shutoff.

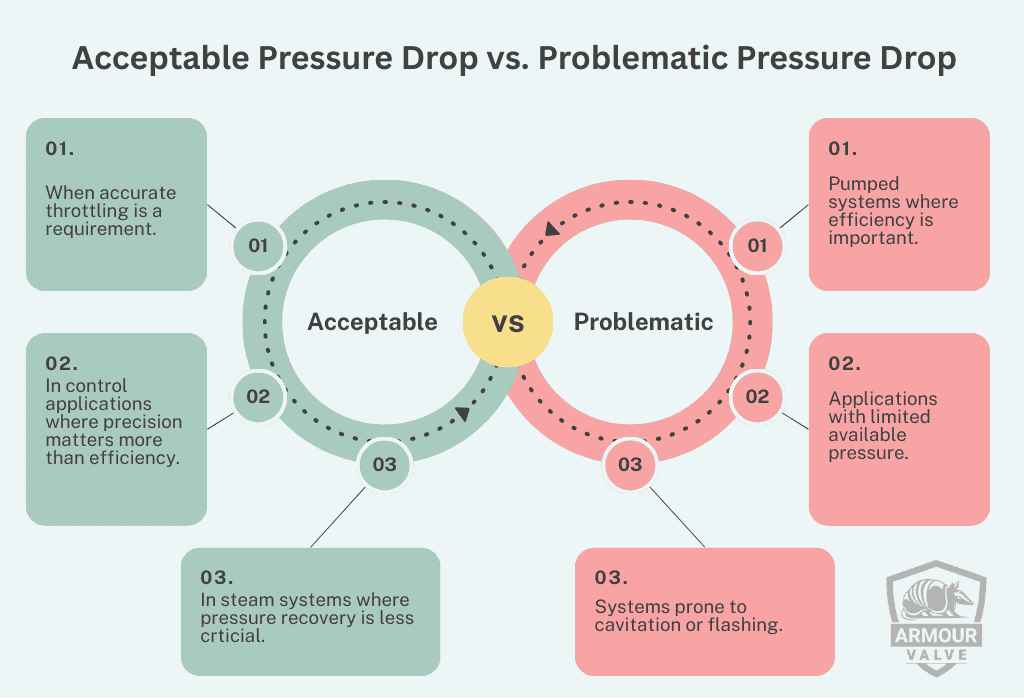

Higher Pressure Drop: The directional changes and restricted flow path increase turbulence and resistance, resulting in a higher pressure drop compared to straight‑through valves like gate or ball valves.

Because of this pressure drop, globe valves are best used in systems where control precision is more critical than flow efficiency — such as steam regulation, cooling water control, or chemical dosing.

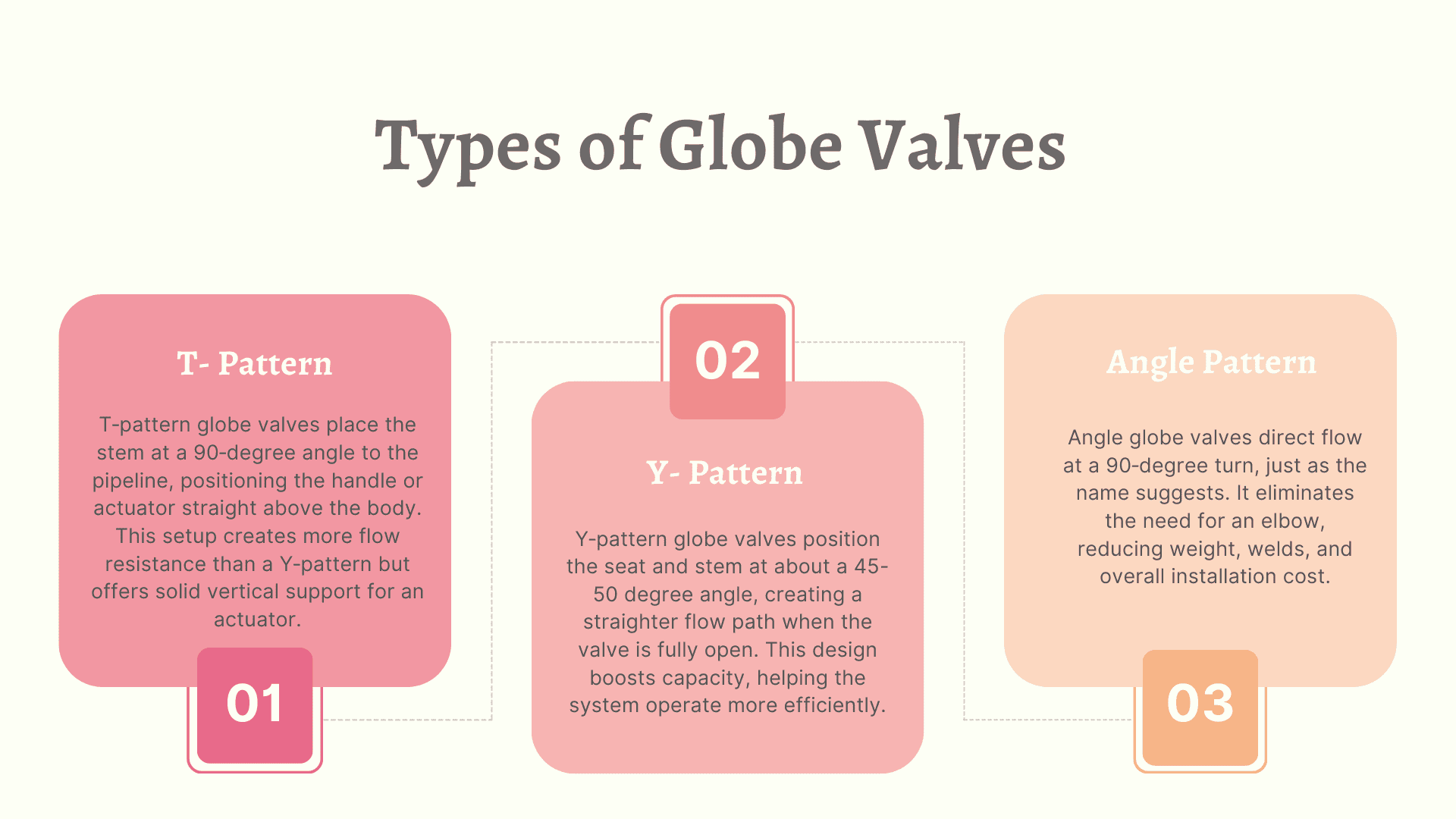

Types of Globe Valves

Globe valves come in several configurations, each suited to different flow and pressure conditions.

Maintenance Considerations

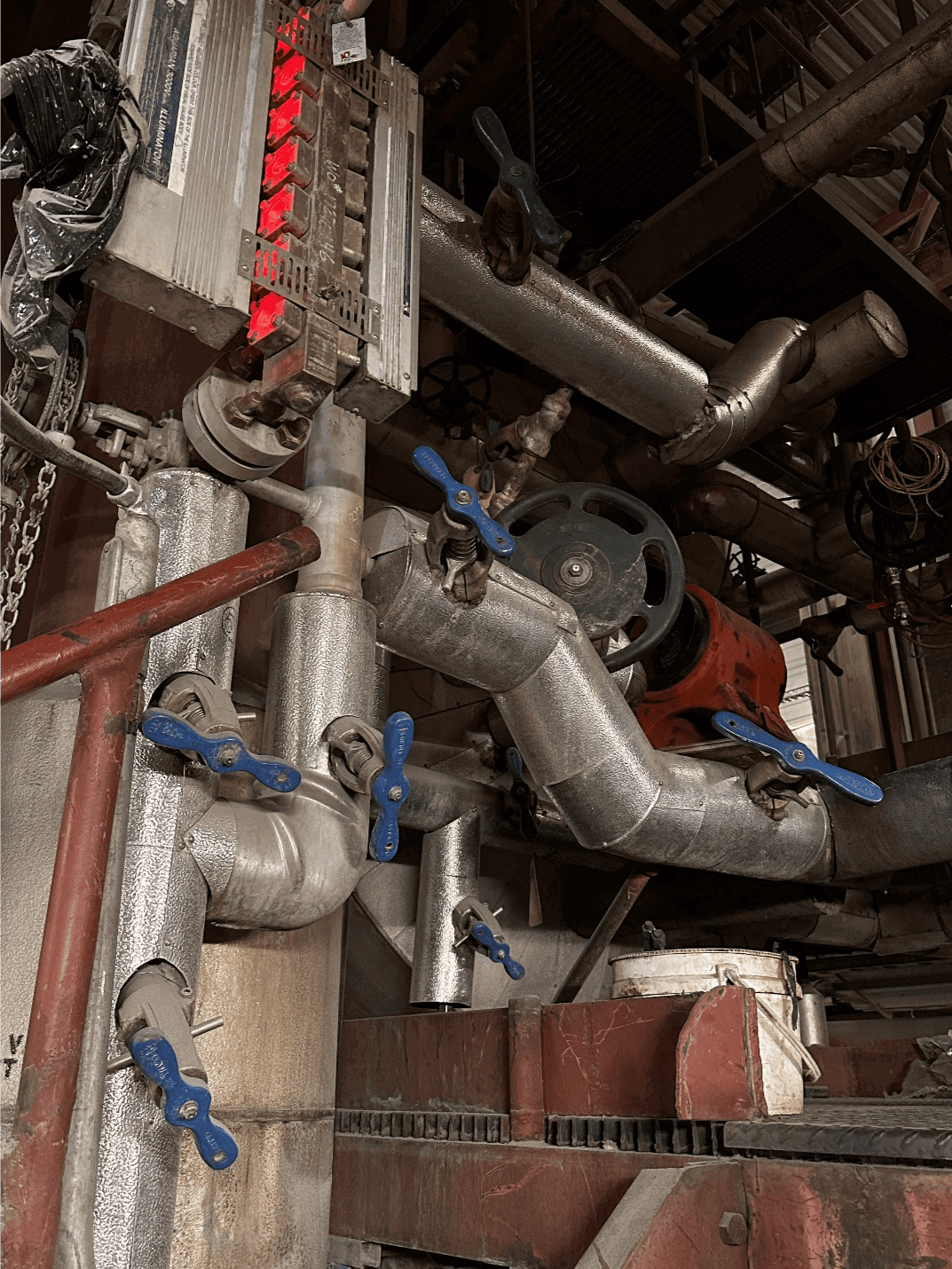

Globe valves show up across industries that depend on precision and reliability—from steam and chemical systems to water treatment, fuel oil, cooling water, and high pressure or high temperature service. Their ability to handle frequent operation makes them a natural fit for control oriented processes.

They offer strong throttling performance, good shutoff capability, and dependable cycling, whether manually operated or automated. The trade off is a higher pressure drop, a bulkier form factor compared to gate valves, and the need for more operating torque. Understanding these strengths and limitations helps ensure the valve is matched to the application in the most effective way.

Globe valves are durable, but like any mechanical component, they require proper maintenance.

Key considerations include:

- Seat and disc wear from throttling

- Stem packing adjustments to prevent leakage

- Inspection of actuators for automated valves

- Repair vs. replace decisions based on service conditions or type of Globe valve

Regular maintenance helps extend valve life and maintain system efficiency. Repair is recommended when the valve body is in good condition and wear is limited to trim components. Replacement is recommended when the body or bonnet is compromised or corrosion is extensive. Explore our ROI Calculator tool to help you make a more data backed decision.

Globe Valve vs. Gate Valve: What’s the Difference?

These two valve types are often compared, but they serve different purposes. If your application requires accurate flow control, a globe valve is typically the better choice.

| Feature | Globe Valve | Gate Valve |

|---|---|---|

| Primary Function | Throttling & Flow Control | On/off isolation |

| Pressure Drop | Higher | Low |

| Operation | Frequent cycling | Infrequent cycling |

| Shutoff Capability | Good | Excellent |

| Best For | Precise flow regulation | Full open/full close service |

| Size Range | Limited in size range, typically available up to 12″ | Available in small and larger sizes typically up to 60″ |

Globe Valve Pressure Drop: What You Need to Know

Pressure drop is one of the most important considerations when selecting a globe valve. Because the flow path changes direction twice, the valve naturally creates more turbulence — and therefore more resistance — than straight through designs. This S‑shaped path forces the media to move under the seat as it enters and then over the seat as it exits toward the outlet. This geometry increases turbulence, which is the trade off for precise flow control.

How to Manage Pressure Drop

- Select a Y-pattern globe valve to reduce flow resistance

- Use multi-stage trim for severe pressure drops

- Ensure proper sizing using Cv calculations

- Avoid throttling too close to the closed position

Conval Globe Valves

Some globe valves used in severe service steam applications are built with maintenance teams in mind. Conval takes this approach seriously. Their modular, in line repairable designs let technicians replace internal components without cutting the valve out of the line — a major time saver in any plant. Features like a pressure seal bonnet provides leak-tight integrity; while still allowing quick access to the trim for inspection and maintenance—proof that thoughtful engineering can extend valve life, even in the toughest environments.

For more than 50 years, we’ve seen the difference this makes in the field. Lower-quality valves often reach the end of their service life in just four to five years. But when plants specify Clampseal Globe Valves from the start, they routinely see service durations five to ten times longer, even under demanding conditions. Conval Globe valves are available in T, Y and Angle pattern styles.

Here’s why so many power plants choose Conval Clampseal Globe Valves:

- Integral Gland Wrench for fast, tool free packing adjustments — a simple feature that makes maintenance easier.

- True in-line serviceability that cuts downtime and reduces maintenance effort; in nuclear settings, it also helps lower man-REM exposure.

- Available in 12,000+ configurations with standard parts that are interchangeable across installations, enabling plants to standardize spares and reduce stocking, procurement, and training costs.

Together, these design choices give operators a valve that’s easier to maintain, lasts significantly longer, and lowers total cost of ownership across the entire lifecycle.

Next Steps: Optimizing Your Globe Valve Performance

Globe valves are an important part of industrial flow control because they offer precision, reliability, and flexibility. Knowing how they work — and where they’re the best fit — can make a big difference in how your system performs.

If you’re considering globe valves for your application, our application specialists are here to help. Contact us to discuss your requirements and find the right solution for your plant.