Issue & Importance

For more than two decades, we have had the privilege of partnering with a leading engineering firm, supporting their Autoclave installations by reliably supplying high-performance valve solutions. This long-standing collaboration reflects our shared commitment to quality, innovation, and engineering excellence. Our vendors know that they can rely on Armour Valve and our suppliers to troubleshoot issues and deliver practical, effective solutions when it matters most.

One of our engineering firm’s gold producers relied on severe service ball valves to manage the extreme conditions of their autoclave system. Over time, the system began experiencing issues when it came time for maintenance on the inlet and outlet lines feeding the autoclave. They were unable to bleed the pressure between the autoclave and inlet piping. This led to the process media solidifying in the piping while the system cooled down.

Because of the autoclave’s extreme temperatures and pressures, any shutdown required a gradual cooldown and pressure release before the unit could be safely accessed—a process that could take around two days, depending on insulation and operating temperature. Once cooled, technicians would manually disassemble the piping and chip away the hardened material—a labor-intensive process that could span up to a week, for 2-3 valves.

After clearing the solidification, restarting the autoclave involved another one to two days to bring the system back up to operating pressures and temperatures. Each maintenance requirement greatly impacted operations by triggering a one-week shutdown at minimum and significantly impacting gold production and operational efficiency.

Solution

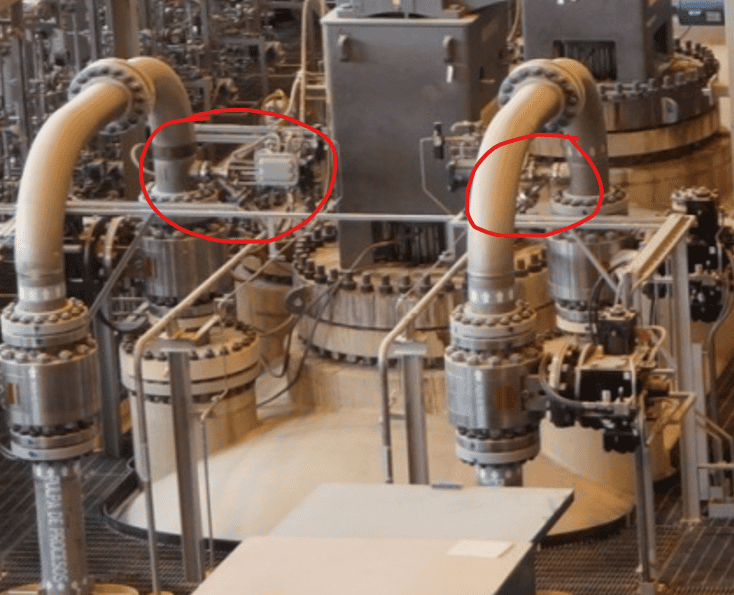

After consulting with Armour Valve and our partner SchuF, the team decided to install SchuF Ram Valves to address the system draining and solidification issues and complementing the ball valves already in place. SchuF Ram valves fully occupy the nozzle, preventing buildup in the inlet and outlet lines. Any solidification now occurs within the autoclave itself—where it’s expected and manageable—rather than in the piping, allowing the system to operate for several years without major interruptions

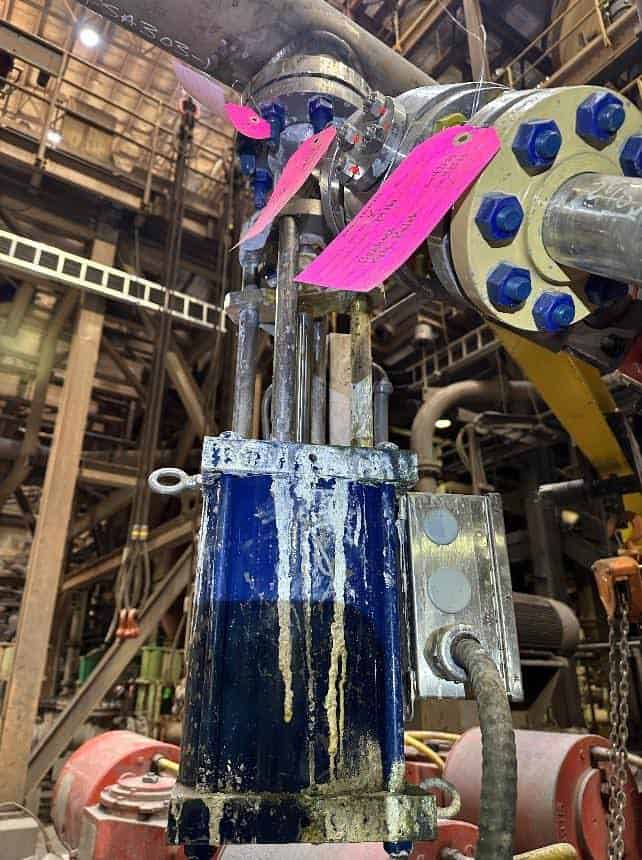

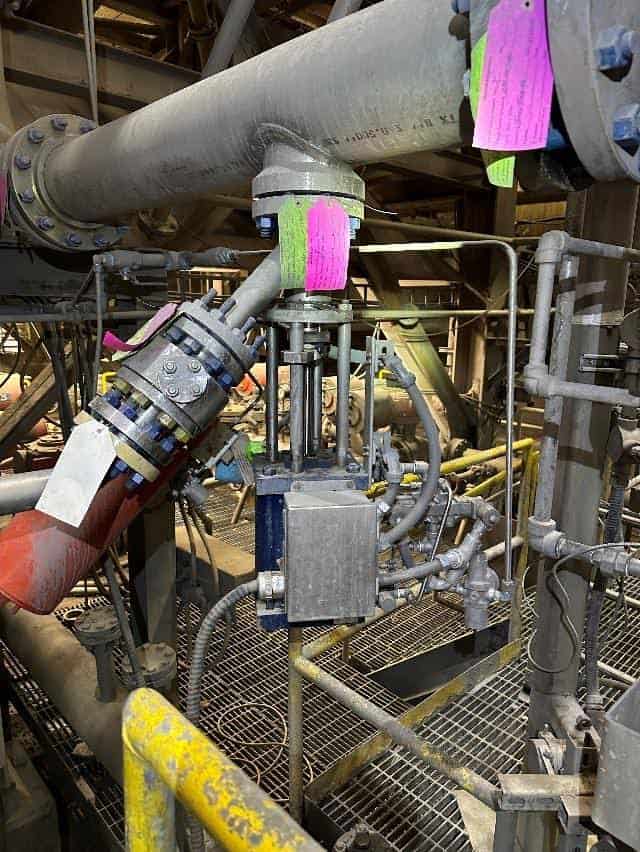

SchuF Ram Valves installed on a autoclave project

Some customers also opt to use the SchuF Ram Valve as a sacrificial valve Unlike ball valves, which deliver an instantaneous pressure surge, the Ram Valve enables a controlled, metered opening. This gradual pressure release reduces mechanical stress on the autoclave’s high-pressure inlet, minimizing wear and tear.

Additionally, SchuF Ram Valves are fully rebuildable, making them a cost-effective and sustainable alternative to ball valves, which are often treated as disposable.

Impact

The introduction of SchuF Ram Valves has significantly extended this gold producer’s maintenance intervals. Instead of halting operations every time a solidification event occurs, they can now run continuously for several years. This shift has led to increased uptime, improved performance, and greater yield and throughput—ultimately boosting productivity and profitability.

SchuF Ram Valves are easily and fully rebuildable. The customer can stock replacement components such as seats and rams, enable on-site refurbishment and reduce both downtime and maintenance costs.

This customer has successfully used SchuF Ram Valves on their autoclaves for over 20 years. Working with SchuF and the engineering firm, Armour Valve has proudly supplied autoclave valve solutions to projects the world over, including the Dominican Republic, Nevada, Russia, and Kazakhstan—the world’s largest operational autoclave once built.

SchuF Ram Valves installed on a autoclave project