When selecting a valve, it’s tempting to focus on the lowest upfront cost. But in most cases, that initial cost is only a fraction of what you’ll spend over the valve’s full lifecycle.

At Armour Valve, we encourage our customers to think beyond the purchase price and consider the total cost of ownership—including maintenance, downtime, repairability, and service life. Investing in a high-quality, repairable valve may cost more initially, but it often delivers far greater value over time through reduced maintenance, extended lifespan, and minimized operational disruptions.

The best decision isn’t always the lower priced option—it’s the one that keeps your system running reliably tomorrow.

When a valve fails or begins to underperform, you’re left with a key decision: repair or replace?

It’s not always a simple answer—especially when factoring in labor, parts, downtime, and disruption to operations. That’s why we created the Armour Valve ROI Calculator tool to help you weigh the options based on your own data—no guesswork and no generic pricing.

This tool puts the power in your hands to make informed decisions that can save thousands of dollars and hours of downtime.

We’ve heard it time and again—engineers, maintenance managers, and procurement teams all asking:

“Is it worth repairing this valve or should we just cut and replace?”

The answer depends on a few key variables: labor costs, valve replacement price, shipping, downtime, special tools needed, and more. These costs and timelines vary by region and operation, so a thorough cost analysis is essential before deciding.

Repair vs. Replace: Practical Examples

Our ROI Calculator is a user-friendly tool designed to help you estimate potential savings—both in cost and hours—when weighing your maintenance options. Simply enter key details like labour rates, valve and parts pricing, and estimated downtime. As you hover over each input field, helpful suggestions will guide you on what to include—such as factoring the cost of a repair kit or estimating crew hours. The results provide a clear, side-by-side comparison of total projected costs and will show your potential percentage savings helping you decide between repairing and replacing a valve.

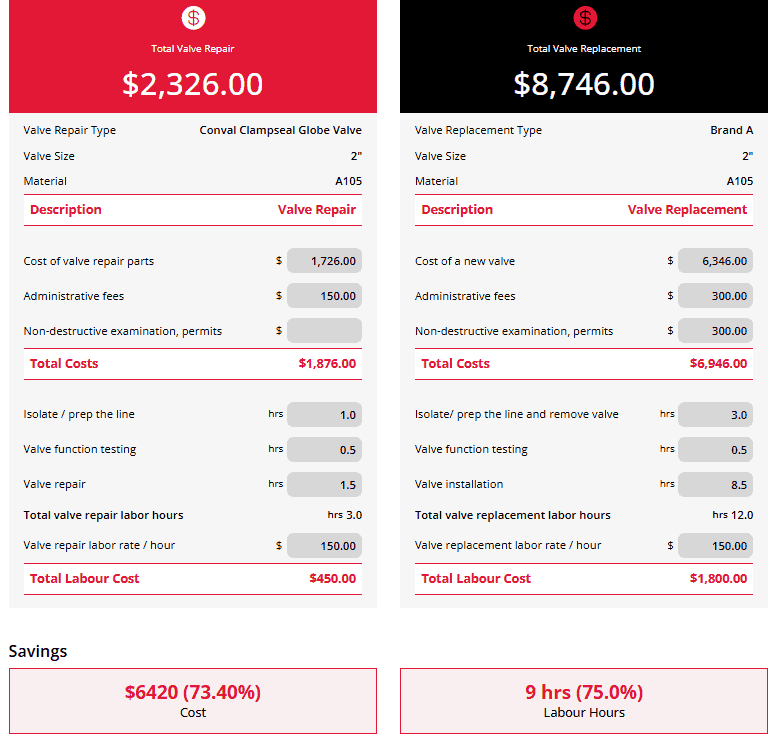

Below are sample use cases demonstrating how the tool can guide repair versus replacement decisions using our Conval Clampseal® Globe Valves and Conval Camseal® Ball Valves.

Conval Clampseal® Globe Valves

Conval’s Clampseal® globe valves are designed with a robust, leak-tight bonnet that enables quick and easy access to internal components for inspection and maintenance.

Example:

A facility with a high-pressure steam line is debating whether to replace a 2” globe valve in A105 material that is currently leaking or to perform a field repair. By entering the site’s labour rate, the valve cost, and estimated repair time, the calculator shows a % cost and time savings in choosing the repair option.

➡ Result: The team avoids pipe cutting, hot work permits, and a multi-day shutdown by opting for repair.

In our example case, repairing the 2” Conval globe valve would save the plant up to 73% compared to replacing the valve. In the past, one of our customers have seen valve repair rates jump from less than 50% to greater than 90% after contracting Armour Valve to perform routine valve servicing and support on their Conval Clampseal® Globe Valves.

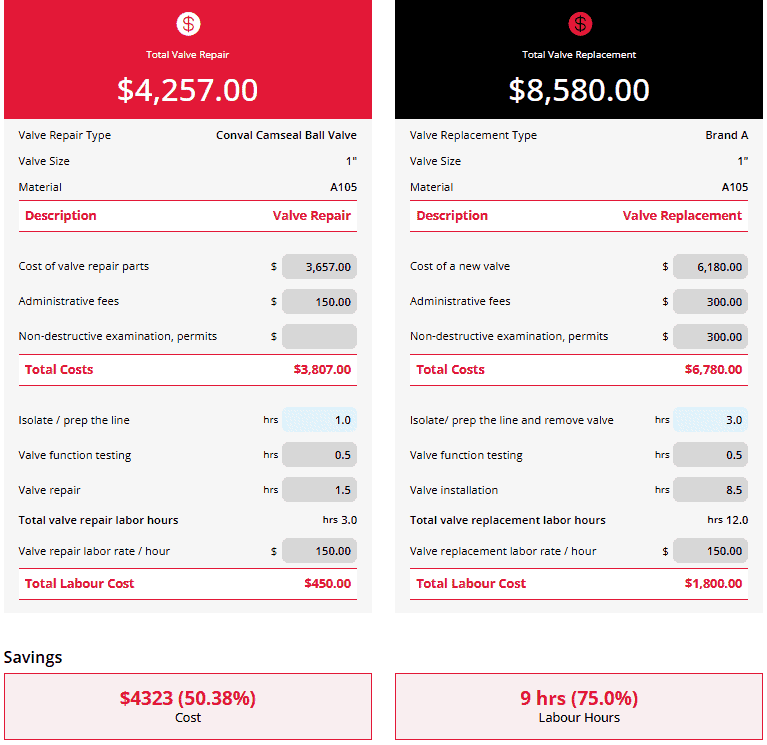

Conval Ball Valves

Conval’s Camseal® metal-seated ball valves are engineered for zero leakage at the body, seat, and stem seals. Thanks to the innovative cartridge-style construction, in-line servicing can be completed in as little as 30 minutes—restoring zero leakage performance. This makes maintenance faster, simpler, and more efficient.

Example:

A plant is considering replacing their 1” A105 ball valve due to seat damage and wear. By inputting values like valve cost, installation time, and labour into our calculator tool—and comparing them to a quick on-site seat and seal replacement—the plant determines that repair is the more cost-effective option.

➡ Result: Repairing takes half the time and saves thousands in labour, with no special tools required. They were also able to complete the renewal in just 90 minutes.

In our example case, repairing a 1” Conval Camseal would save up to 50% compared to replacement costs. Over an 8-year period, one of our customers cycled a Camseal® valve approximately 87,000 times before it required its first cartridge change.

Making Valve Decisions Easier: What Repair Saves You

To make your decision easier, we’ve outlined replacement steps avoided with opting for valve repair over replacement. Our comparison clearly highlights how repair eliminates many of the time-consuming and costly steps involved in replacement.

The table below uses the following abbreviations “N” for “No” and “Y” for “Yes”.

| Replacement Steps Avoided with Valve Repair | Repair | Replace |

| Permit type | Cold | Hot |

| NDT (UT, LPI, X-ray) and PWHT (if required) | N | Y |

| Welding preparation (Welding procedures, Welder Qualification) | N | Y |

| Remove valve from line | N | Y |

| Pipe fitting | N | Y |

| Douse inside of pipe area with inert gas | N | If needed |

| Welding | N | Y |

| Hydro test welded joints | N | Y |

Repair Isn’t Always the Answer—But It’s Often Overlooked

There are times when replacement makes more sense—like when valves are obsolete, unsafe, or damaged beyond reasonable repair.

But in many cases, a smart repair strategy saves you more—in dollars, time and stress.

Stop guessing—start calculating! Let Armour Valve’s ROI calculator help you evaluate valve repair vs. replacement using your own data for accurate results.

Need help assessing a valve or booking a service visit? We’re happy to help! Email us at customercare@armourvalve.com and a member of our team will connect with you.