In the fight against climate change, carbon capture emerges as a pivotal technology. This process involves capturing CO2 emissions from sources like power plants and industrial facilities before they reach the atmosphere. The captured CO2 is then stored underground or reused in various applications. With the capability to capture over 90% of CO2 emissions, carbon capture technology is playing a crucial role in global efforts to reduce greenhouse gas emissions by 2050. Carbon Capture and Storage (CCS) is emerging as a critical technology for reducing industrial carbon emissions.

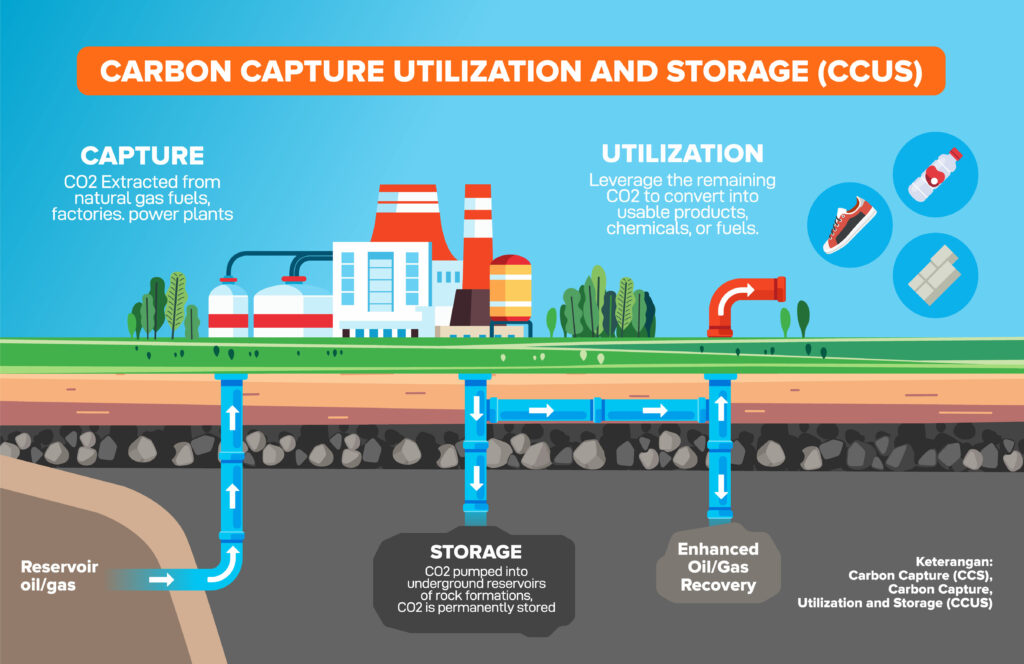

The process involves three key steps:

- Capture: CO2 is captured from large-scale industrial infrastructure, including power plants, manufacturing, concrete, petrochemicals, and steel manufacturing.

- Transport: The captured CO2 must be transported to natural storage sites. Pipelines are the most economical form of transport, although rail, truck, or ship can also be used.

- Storage: CO2 is injected deep into natural underground reservoirs, often into geological formations like oil & gas fields.

Valves play a vital role in this process and must meet special requirements, including being capable of handling high pressures. Boehmer GmbH is a leader in this industry, addressing the unique challenges of CCS with durable, high-performance designs that make them a key component in sustainable environmental solutions.

Carbon Capture Utilization and Storage Process Diagram

Boehmer’s Experience in Carbon Capture

At Armour Valve, we understand the importance of carbon capture in addressing environmental challenges. This understanding is deepened by our close work with Boehmer, a company with experience in carbon capture initiatives. Boehmer has been at the forefront of supplying specialized valves for these systems, significantly contributing to the efficiency and success of carbon capture projects. Armour Valve is an exclusive representative and stocking distributor for Boehmer’s ball valves in Canada.

Boehmer is involved in several carbon capture projects in Canada. One such project involves a 400-kilometre CO2 transportation line that could eventually link over 20 carbon capture and storage (CCS) facilities to a carbon storage hub. This is a crucial part of an initiative to reduce carbon dioxide emissions, using a proven process that captures CO2 before it’s emitted, transports it to a secure location, and stores it permanently over one kilometre underground.

Boehmer has supplied flanged valves for CO2 measurement and metering in various sizes. Its products include fully welded valves and forged materials, with design adjustments for CO2 capture. Boehmer has participated in large-scale projects requiring high-pressure valves, up to Class 1500.

Boehmer Fully Welded Ball Valves

Valve Challenges and Solutions in Carbon Capture Applications

In carbon capture applications, the challenges surrounding valve design are numerous. A key issue is the need for valves that can handle the unique properties of CO2, especially under varying temperature and pressure conditions. Boehmer has addressed these challenges innovatively. Here are some of the design considerations that make Boehmer the valve of choice for CO2 and hydrogen applications:

- Double-Piston-Effect Combined with Self Relieving Seat (DIB-2): With this design the seat rings tighten independently of the actual pressure relations. Self-relieving of a downstream seat allows for potential over pressure of the cavity to relieve downstream to the lower pressure. This is needed as CO2 at high pressure behaves like a liquid. This design feature eliminates the need for an external pressure relief mechanism.

- Stem Sealing Components: The O-rings used in this area are certified for CO2 service.

- Seat Design: The seat involves a proven design specifically for CO2.

- Low Temperature Tolerance: The valves are crafted to withstand low temperatures, which is critical in handling CO2 effectively.

- Material Strength: Using forged materials, Boehmer valves are built to endure the demanding conditions of carbon capture processes.

- Versatility in Size and Pressure: Catering to large-scale projects like the 400-kilometre CO2 transportation line project mentioned above, Boehmer’s valves range up to 1500 class and sizes up to 36 inches, demonstrating their adaptability to various project requirements.

Armour Valve Can Help Provide Solutions for Carbon Capture Applications

Boehmer ball valves are well suited for carbon capture projects as they are designed to meet the specific demands of this application. These valves represent the pinnacle of innovation and reliability in the industry.

As the exclusive distributor of Boehmer valves in Canada, Armour Valve is your go-to source for top-tier solutions in carbon capture technology. We invite you to contact us for a consultation to learn more about how Boehmer ball valves can enhance your carbon capture initiatives. Together, we can play a pivotal role in the global effort to combat climate change.