Problem:

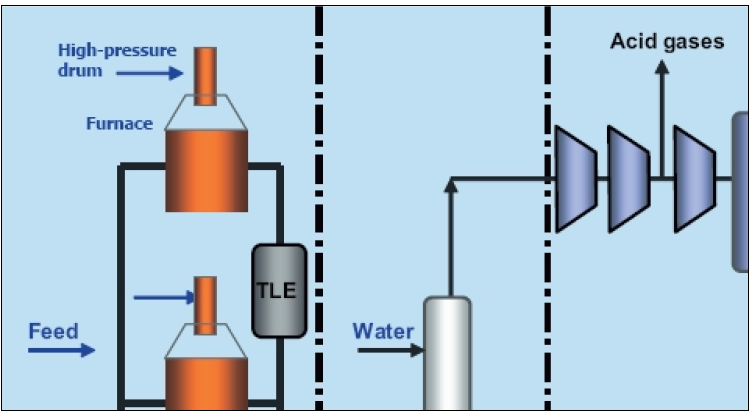

A Canadian ethylene plant, originally built in the 1980s, underwent several expansions as market demand for ethylene grew in the plastics industry. Valves from a variety of manufacturers, often purchased on a best price basis, were installed in the heater feed water and boiling piping systems.

Over time, significant numbers of valves were cut out of piping and replaced due to various performance issues. In addition, feedwater isolation valves were being throttled during startup causing rapid wear and leading to frequent replacement.

Feedwater is fed to the furnace in precision amounts to be converted to steam

Solution:

Maintenance personnel noted that the Conval Clampseal demonstrated fewer issues involving packing or seat leakage than the other installed valves.

A mechanical engineer assigned to the ethylene heaters decided to perform a controlled test by installing a complement of Conval Clampseal™ valves on one of the heaters, including:

- 1” to 3” Class 1500, Y-globes

- 1.5” Conval angle pattern throttling valve for metering flow during heater startup

Conval Clampseal Throttling Valve

Impact:

The test period lasted three years, during which periodic inspections were conducted with no reported issues.

Conval Clampseal valves exceeded expectations and during the next shut down, were installed on the remaining ethylene heaters at the plant.

Armour Valve has provided on-site training for operations and maintenance staff and worked with the plant to develop procedures for heater startup to ensure proper operation of the valves and has

The Conval Clampseal™ valves became the standard for high-pressure feed water, condensate, and steam applications at the plant.