Reducing carbon emissions has become a top priority for energy and industrial facilities worldwide. As they face increasing pressure to comply with environmental regulations and embrace sustainable practices, optimizing every aspect of the operation to reduce energy use and emissions is crucial. Valves sometimes overlooked but essential components in energy and industrial processes, present opportunities for reducing emissions through enhanced performance and leak prevention. Choosing the right valve solutions can help improve operational efficiency while also making a meaningful impact on the carbon footprint of a facility. This article delves into how innovative valve technologies are paving the way for a carbon-neutral future, highlighting key solutions that can help energy and industrial facilities achieve their carbon reduction goals.

Benefits of Implementing Sustainable Valve Solutions

Upgrading older infrastructure with sustainable valve solutions can enhance energy efficiency and provide emissions control, ensuring that systems operate at peak performance while minimizing impact on the environment.

In one such example, a Trauma 1 Emergency Medical Center in California faced poor performance and limited distribution flow in their Combined Heat and power (CHP) chilled water system, leading to excessive pumping energy, low delta T (temperature difference between return and supply air) building performance, and a 50% loss in chiller capacity, threatening the ability to meet cooling demands across 16 critical buildings. They decided to install the Flow Control Industries DeltaPValve® across all buildings as part of a retrofit upgrade. The retrofit resulted in significant improvements, including an increase in delta T from 8-9°F to 15°F, a 50% reduction in energy savings, and enhanced system capacity, allowing the center to maintain high efficiency and comfort levels while reducing equipment usage.

Sustainable valve solutions can also extend the operational lifespan of your existing equipment and lead to savings, allowing you to get more value from your investments and adapt to evolving environmental requirements without needing complete system overhauls. Our in-line repairable Conval valves, for example, are designed to deliver the lowest life-cycle costs, ensuring long-term efficiency and reliability.

Additionally, incorporating sustainable valve solutions helps future-proof your operations, ensuring compliance with current and anticipated environmental regulations. This proactive approach not only avoids regulatory penalties but also positions your business for long-term success.

Valve Solutions for Carbon Reduction

Choosing the right valve solution is a positive first step for energy and industrial businesses looking to reduce emissions. Armour Valve, together with our partners, are dedicated to offering valve technologies that help reduce carbon emissions, improve efficiency, and support sustainable practices. Our focus on sustainability motivates us to supply valve solutions that go beyond industry standards for environmental performance. In this section, we’ll highlight some of Armour Valve’s key valve solutions designed to aid in carbon reduction across diverse energy and industrial applications.

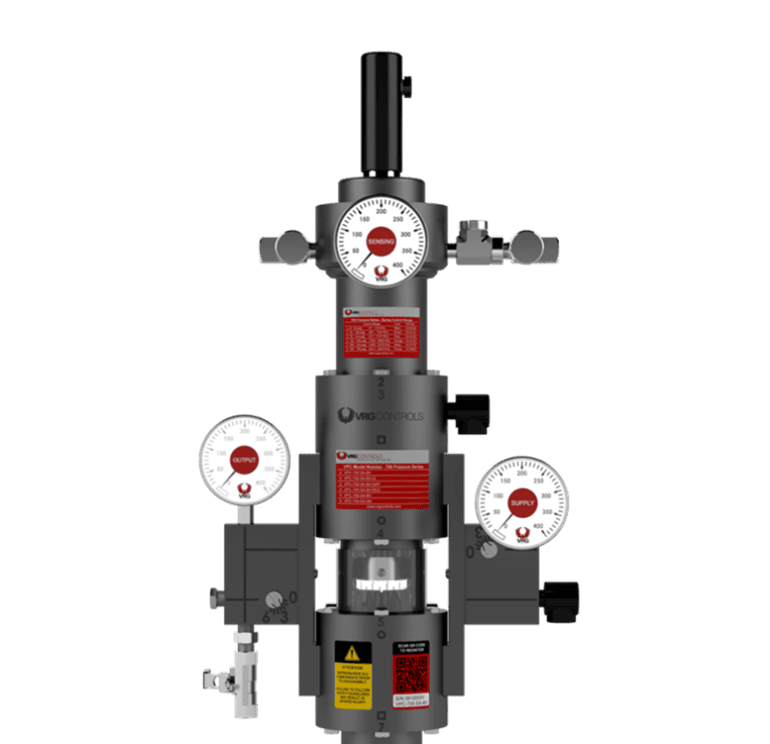

VRG Valve Pressure Controllers

Developed by VRG Controls, the Valve Pilot Controller (VPC) is an innovative solution designed to support carbon reduction efforts in the natural gas industry. By optimizing the performance of pneumatically actuated control valves, the VPC plays a crucial role in cutting down emissions directly at their source. Its advanced design ensures zero steady-state emissions, offering an innovative solution for companies committed to minimizing their environmental footprint.

Designed with sustainability at its core, the VPC zero steady-state emissions design eliminates atmospheric emissions when configured to discharge into a pressure system. This capability makes it an essential tool for companies aiming to meet stringent environmental standards and reduce their carbon footprint. The modular design of the VPC provides unmatched flexibility, reducing the number of tubing connections needed and simplifying installation and maintenance. Constructed from military-grade alloy, the VPC ensures superior corrosion resistance, extending the lifespan of the valve and reducing the need for frequent replacements.

Designed with sustainability at its core, the VPC zero steady-state emissions design eliminates atmospheric emissions when configured to discharge into a pressure system. This capability makes it an essential tool for companies aiming to meet stringent environmental standards and reduce their carbon footprint. The modular design of the VPC provides unmatched flexibility, reducing the number of tubing connections needed and simplifying installation and maintenance. Constructed from military-grade alloy, the VPC ensures superior corrosion resistance, extending the lifespan of the valve and reducing the need for frequent replacements.

With only two repair kits required to cover the entire product range, the VPC minimizes downtime and lowers maintenance costs. Additionally, its compatibility with other manufacturers’ pneumatic control valves allows for seamless integration into existing systems. By utilizing these Valve Pressure Controllers, companies are investing in a reliable, efficient, and sustainable solution to drive carbon reduction efforts and support greener operations.

VRG Red Ox Regulators

Another zero-emission solution from VRG controls, is the Red Ox Regulator. The Red Ox Regulator is an advanced gas pressure regulator designed for high-efficiency gas transmission and utility applications. It boasts zero steady-state emissions and integrates “carbon capture” technology from Oxford Flow, ensuring that no atmospheric emissions are produced for natural gas, hydrogen, and hydrogen-methane blends.

Its compact, full stainless-steel construction utilizes a patented piston control system, replacing traditional diaphragms to enhance reliability and lower maintenance costs.

Its compact, full stainless-steel construction utilizes a patented piston control system, replacing traditional diaphragms to enhance reliability and lower maintenance costs.

The regulator is engineered to handle up to 100% hydrogen content with zero atmospheric emissions. Its advanced true axial flow design and bubble-tight shutoff provide exceptional performance even in the most challenging conditions. Featuring a single moving part for streamlined maintenance and a robust protected seat insert for dependable shutoff, this regulator excels in efficiency and reliability. Available in wafer and top-entry designs, it is rigorously tested and proven for 100% hydrogen use.

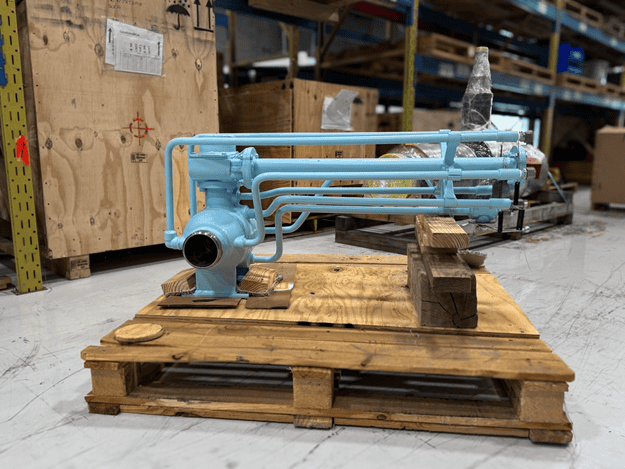

Boehmer Fully Welded Ball Valves

Boehmer has become the go-to choice for isolation valves in natural gas, hydrogen, and district energy hot water systems, setting the standard for performance and reliability.

Often overlooked in district energy systems, valves play a critical role in isolation and system integrity. Boehmer’s forged, fully welded ball valves for hot and chilled water applications are engineered for long-term reliability and performance. Their design eliminates intersecting weld seams, reducing potential leak paths and ensuring a robust, maintenance-free solution ideal for buried service.

Within carbon capture, Boehmer valves are designed to handle the high pressures and rigorous conditions involved in capturing CO2 emissions from industrial sources. Their innovative design includes features like the double-piston-effect technology and self-relieving seats which optimize performance by independently adjusting seat rings and relieving excess pressure internally. This design is essential for handling CO2 at high pressures when it behaves like a liquid and eliminates the need for external pressure relief mechanisms, ensuring efficient and reliable carbon capture.

Within carbon capture, Boehmer valves are designed to handle the high pressures and rigorous conditions involved in capturing CO2 emissions from industrial sources. Their innovative design includes features like the double-piston-effect technology and self-relieving seats which optimize performance by independently adjusting seat rings and relieving excess pressure internally. This design is essential for handling CO2 at high pressures when it behaves like a liquid and eliminates the need for external pressure relief mechanisms, ensuring efficient and reliable carbon capture.

For hydrogen blending, Boehmer valves are crafted to support the shift to cleaner energy. They are specifically designed to handle hydrogen’s unique characteristics, including its low temperature and pressure variations, while utilizing materials that prevent hydrogen embrittlement. Boehmer’s API6D ball valves are also certified H2-ready for 100% hydrogen service.

Committing to Carbon Reduction

As the drive toward a more sustainable future accelerates, the importance of innovative technologies that reduce carbon emissions cannot be overstated. By integrating high-performance, carbon-reducing valve solutions, industries can not only comply with ever-tightening environmental regulations but also improve operational performance and reduce costs over the long term.

If you’re ready to take the next step toward reducing your company’s carbon footprint and improving process efficiency, consider integrating sustainable valve solutions from Armour Valve. Contact our team at sales@armourvalve.com to explore how our innovative products can meet your specific needs and support your sustainability goals. For more insight into our commitment to environmental responsibility, download our purpose report today and join us in creating a net-zero future.