When it comes to industrial valves and fittings, quality and reliability are non-negotiable. Whether you’re working in power generation, mining, or district heating, the right equipment ensures safety, efficiency, and long-term performance.

At Armour Valve, we take pride in offering high performance valves and fittings from leading manufacturers around the world. Our diverse portfolio ensures that our customers get the best solutions for their applications, whether they need special materials, sizes or industry certifications. As a proud Canadian business established in 1971, Armour Valve is excited to spotlight fellow Canadian manufacturers—Frontier Valves and Hiltap™ Fittings within our product lineup.

While purchasing locally manufactured solutions isn’t always an option, when its possible, supporting Canadian businesses means reduced shipping times, fewer delays and the strengthening of our local economy that supports local employment opportunities.

Frontier Valves and Hiltap™ Fittings stand out as Canadian manufacturers, delivering the level of innovation, durability, and performance that our customers expect from Armour Valve. Let’s take a closer look at what makes Frontier Valves and Hiltap™ Fittings a smart choice for your operations.

Frontier Valves

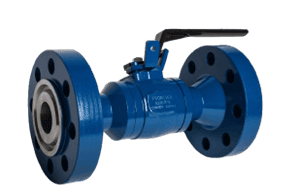

Are you using three-piece threaded or flanged ball valves in your plant operations? If your plant operations rely on three-piece threaded or flanged ball valves, consider Frontier Valves. Made in Canada, these valves can be custom designed to meet your specific needs. Located in Edmonton, Alberta, Canadian and family-owned Frontier Valve is known for its valve manufacturing expertise and ability to bring your vision to life with tailored engineered solutions.

The S3 and I3 model ball valves have earned a strong reputation for durability, making them a top choice for various applications. Whether you need a two-piece or three-piece design for high-pressure conditions, these valves are built to perform. Made with high-quality forged steel, each valve is 100% hydro tested for quality assurance and features a fire-safe design. They also come with locking handles, blow-out proof stems, and easy-to-adjust packing, ensuring they’re ready to withstand tough environments, including low temperatures and sour service. Plus, with options for exotic materials, full material traceability, and CRNs, you can be sure you’re getting a reliable, long-lasting solution. Standard three-piece threaded ball valves come in 1500 ANSI Class/3000 psi, with proprietary Teflon carbon blend seats that reduce torque for smoother operation. Also, with in-house engineering and design, you can count on valves built to your exact specifications.

Hiltap™ Fittings

In high-pressure, high-temperature, or critical fluid transfer applications, the right connection technology is crucial to ensuring reliable performance. Hiltap™ Fittings, based in Calgary, Alberta is a division of OPW Engineered Systems, and manufactures couplings and connectors designed to excel in severe service environments. With a focus on leak-proof integrity, user-friendly design, and enhanced safety, their solutions set the standard for reliability and performance where it matters most.

Hiltap™ Fittings RapidLOK™ series includes a range of safety quick couplings designed to prevent leaks and stay securely connected under pressure. Great examples of these are their 3TL coupling, 415/425/490 series and locking quick connect built for reliable, hassle-free performance.

The 3TL Coupling features a metal-to-metal wedge seal for a secure, leak-free connection—no hammer union required. That means less operator strain, faster connections, and no more replacing worn-out seals. Designed to handle extreme temperatures and pressures, the 3TL is a high-performance solution for demanding fluid transfer loading applications. It also replaces traditional hammer unions and CAM locking couplings, offering unrestricted flow and no variation in pipe diameter for quicker and easier connections.

For those needing a versatile, bolt-free solution, the RapidLOK® 415/425/490 Series provides simple, safe, and reliable connections. These couplings feature a reusable metal-to-metal seal with an optional secondary enviro O-Ring, ensuring durability and leak-free performance. The automatic pressure venting adds an extra layer of safety, while the no-bolt design allows for faster hook-ups without special heat treatments. Built to handle tough jobs, the RapidLOK® series saves time and effort in high-pressure applications.

For a secure, tool-free connection that won’t disengage under pressure, the LQC (Locking Quick Connect) is a reliable choice. It’s engineered to stay securely connected, even under pressure, with a simple 1/4-turn operation for fast, tool-free hookups. This minimizes operator strain while maintaining a reliable seal. The LQC takes safety a step further by preventing uncoupling if residual or line pressure is present, making it an ideal solution for hoses and loading arms in critical fluid transfer applications.

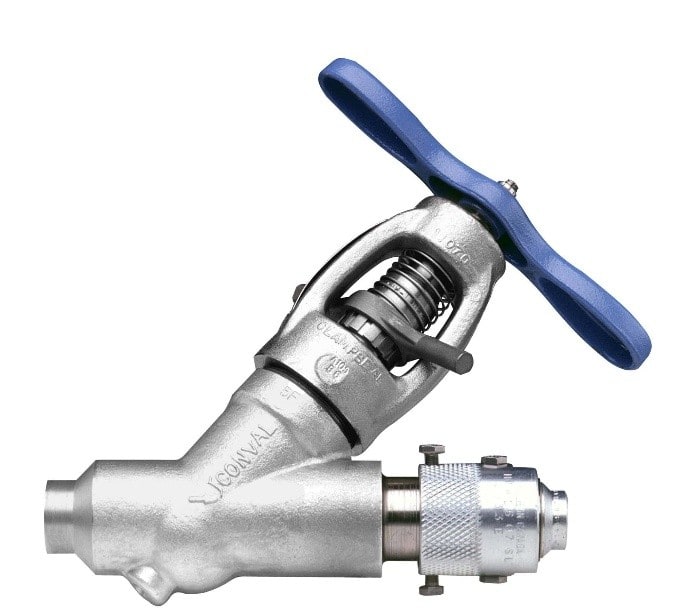

When it comes to venting and draining high-pressure steam and heavy oil piping, traditional bull plugs can be risky. In fact, bull plugs have been linked to several fatalities. Conventional bull plugs allow the thread to encounter liquid, drastically shortening the plug’s lifespan alongside corrosion and rust making it dangerous to handle. The SaVD™ Safety Seal Cap is a proven, CRN-registered solution that offers a safer, more reliable solution designed specifically for SAGD steam and heavy oil applications. A collaboration between two manufacturers that combines a Conval Clampseal® Globe Valve with a Hiltap™ Fitting Safety Seal Cap. This SaVD™ Assembly is designed to replace high pressure bull plugs used in venting and draining SAGD steam and heavy oil piping. This allows for the safe draining and venting of piping systems.

When it comes to venting and draining high-pressure steam and heavy oil piping, traditional bull plugs can be risky. In fact, bull plugs have been linked to several fatalities. Conventional bull plugs allow the thread to encounter liquid, drastically shortening the plug’s lifespan alongside corrosion and rust making it dangerous to handle. The SaVD™ Safety Seal Cap is a proven, CRN-registered solution that offers a safer, more reliable solution designed specifically for SAGD steam and heavy oil applications. A collaboration between two manufacturers that combines a Conval Clampseal® Globe Valve with a Hiltap™ Fitting Safety Seal Cap. This SaVD™ Assembly is designed to replace high pressure bull plugs used in venting and draining SAGD steam and heavy oil piping. This allows for the safe draining and venting of piping systems.

Hiltap™ Fittings also manufactures Burst Pups to prevent conventional well damage. This saves costs by quickly filling a well hole with cement – preventing the well from being damaged by the build-up of gas. Hiltap™ fittings are built to make fluid connections easier, safer, and more reliable. With innovative, high-quality designs, they help reduce maintenance costs, save time, and improve efficiency. Designed for durability and ease of use, they provide a secure fit while ensuring safety for operators. Plus, they can be customized to meet your specific needs, ensuring the right solution for every job.

Book a Product Consultation

At Armour Valve, we proudly offer a diverse range of high-quality products from both Canadian manufacturers like Frontier Valves and Hiltap™ Fittings, as well as our trusted global partners. While local solutions like Frontier Valves and Hiltap™ Fittings bring the added benefits of supporting the Canadian economy, we also recognize the exceptional value and innovations our international suppliers bring to the table.

We understand that where you choose to do business is an important decision. While many Canadians are choosing to support local businesses, it’s important to remember that companies—and the people behind them—aren’t defined by their location or the policies of their government. Our solutions not only meet the highest standards but also help our Canadian clients support the energy and industrial needs of communities across Canada.

Our goal remains to offer you the highest quality products and services, with a strong focus on operational efficiency and excellence. Whether you’re looking for custom-designed, Made-in-Canada ball valves or advanced fittings from our global network, Armour Valve provides reliable, high-performance solutions that fit your specific needs. No matter where our products are manufactured, you can trust that we’re delivering the best solutions to help you achieve success in your projects.

Reach out today at sales@armourvalve.com or 1-800-268-3508 to learn more about our full range of solutions and how Armour Valve can support your next project!