Issue & Importance

A mining company was facing significant challenges with knife gate valves throughout their plant. Particularly affected were pump intake and discharge in slurry applications where the presence of sand was causing severe buildup, making valve operation difficult and unsafe.

Over time, the accumulated sand made it nearly impossible to open and close the valves manually. Operators were forced to use pipe wrenches and apply excessive force—sometimes requiring two workers—to turn the valve handles. This led to serious safety risks, and in one instance, an operator snapped a handle, resulting in an onsite injury.

After the accident, the company sought to enhance safety by modifying the valves to be operable with a rad gun, incorporating spent nuts from their rod mill, stops, and a reaction arm for controlled opening and closing. However, this solution introduced new problems, including over-torquing of valve stems, which prevented proper sealing. Despite efforts, the company continued to struggle with operational inefficiencies and safety concerns, highlighting the need for a more effective and reliable solution.

Solution

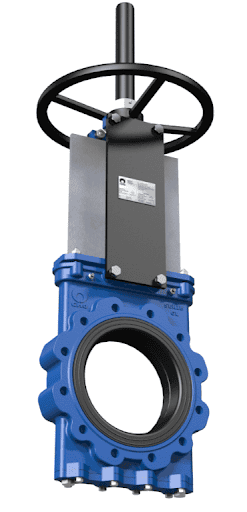

To address the mining company’s safety and operational challenges, Armour Valve recommended the CMO GL Series Sleeved Knife Gate Valve, specifically designed for demanding slurry applications.

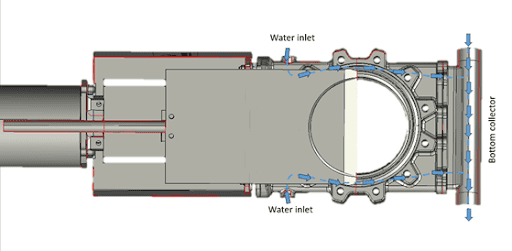

Unlike standard knife gate valves that struggle with sand accumulation, the GL Series incorporates built-in flushing ports that allow pressurized water to be introduced into the valve body. This continuous flushing action helps dislodge and remove sand and solids, preventing buildup that can lead to operational failures. Additionally, the valve features a bottom collector, ensuring efficient extraction of debris from the system.

Both CMO’s GL and GD series are specially designed for slurry applications and prevent sand accumulation by flushing pressurized water inside the body and extracting the sand through the bottom collector (as shown in image).

CMO’s bidirectional wafer-design knife gate valve features a durable Monoblock cast iron body and stainless-steel gate with dual rubber sleeves, ensuring high flow rates with minimal pressure drop. It also offers customizable seat materials to suit a variety of applications.

Impact

Successful implementation of the CMO GL Series Sleeved Knife Gate Valve has the potential to deliver operational and safety benefits for the mining company. By preventing sand accumulation and ensuring smooth valve operation, this solution is expected to reduce mill downtime by up to 24 hours per year providing efficiency gains for the plant.

The company previously spent approximately 56 hours per year replacing an average of nine 6-inch valves and five 8-inch valves, each taking about four hours to replace. With the new CMO solution, they stand to save up to 24 hours annually. By extending valve lifespan and reducing maintenance frequency, the new solution presents a strong business case for long-term cost savings and operational improvements.

With safety as the primary driver behind this upgrade, the CMO GL Series Knife Gate Valve represents a critical step toward safer and more efficient operations, ensuring long-term reliability for the mining company’s slurry systems.

While the full results at this site are still unfolding with the valves recently being installed, the GL Series has already proven its value in other challenging slurry applications. In one project, CMO GL Series knife gate valves were used to transport slurry over a 1 km pipeline from the plant to a new tailings dam. The valves delivered reliable performance under high-pressure conditions, maintaining steady flow with minimal pressure drop. Their internal design effectively prevented solids buildup in the seat area, reducing maintenance needs and ensuring smooth, uninterrupted operation throughout the system.

This proven performance in a demanding slurry environment gives us confidence that the GL Series will deliver similar results for our customer. However, we will provide an update within the next 18 months once we gain more insight into the valve’s impact on operational efficiency and maintenance requirements.