Purchasing low-cost valves can be tempting, especially on a project with tight budget constraints. While this saves dollars in the short run, plant personnel may be faced with costly issues once the plant is operating – shorter valve life cycles, leakage, forced shutdowns, repairs, replacements and, in the worst case, accidents. While it may carry a higher up-front cost, investing in the right quality valve solutions reduces direct maintenance costs and lost production due to downtime, ultimately providing a better return on investment over the service life of the valve.

Increased emphasis on ESG and sustainability reporting will require businesses to adjust their thinking about cost to include the social and environmental impacts of procurement choices from “cradle to grave” or, in a more circular way, from “cradle to cradle” when reuse or recycling are possible. Reducing waste and lowering safety and environmental risks deliver additional value add beyond up-front cost savings when ESG impacts are considered in procurement.

Think Lowest Total Cost of Ownership (TCO)

Our goal at Armour Valve is to help our customers select solutions that will deliver the best overall long-term value. We are often called on to help replace “problem valves” that wear out in service much more quickly than anticipated. Our customers are surprised at the full cost of inferior valves selected primarily on price or because they meet minimum specification requirements.

Below is an oversimplified example of TCO for valves that have a significant difference in purchase price to help illustrate this point. The higher quality valve can be repaired in-line at lower cost and with longer time between maintenance. Without accounting for the full TCO that would include additional acquisition costs, disposal costs, and lost production, the high-quality valve that requires less frequent maintenance is the clear winner. The $9,700 saved up front by purchasing the low-cost model is negated in the first 3 years due to maintenance.

| Cost Category | Low-Cost Option | High-Quality Option | ||

| Purchase price | $16,000 | $25,300 | ||

| Installation cost | $7,000 | $7,000 | ||

| Maintenance cost per cycle | $7,000 | $3,000 | ||

| Maintenance cycle (years) | 1 | 3 | ||

| Expected lifespan (years) | 3 | 15 | ||

| Total maintenance | 10 | 4 | ||

| Total replacements | 5 | 1 | ||

| Total Maintenance Cost | $70,000 | $12,000 |

| Total Replacement Cost | $51,000 | $28,300 |

| $121,000 | $40,300 |

Although lowest total cost of ownership can be achieved on your own, working with a reputable supplier can help you save time sourcing a solution. It also allows you to work with industry experts to help you find the best-fit solution for your specific application and support you long after your initial purchase.

When researching a valve supplier, we recommend that you confirm up front how they approach maintenance, whether they stock or can provide replacement parts in a timely manner, and the expected cost and frequency of replacement in the application. These are crucial factors when determining your total cost of ownership.

Valve Solutions That Help You Save Money

Conval

Conval manufactures valves for the world’s most demanding service that can be repaired in-line, saving time and money and reducing waste and downtime. The modular design ensures that parts that are manufactured today are compatible with valves that have been in service for years. We know of Conval valves that have been performing in service for decades.

Boehmer

Boehmer District Energy ball valves offers durability ensuring several years of corrosion free performance. A fully welded trunnion mounted design ensures there are no leak paths and that the valve is able to operate and fully seal even after several years in service. It is designed to be maintenance free under normal operating conditions, making it especially attractive for buried service where they can perform in service 30+ years.

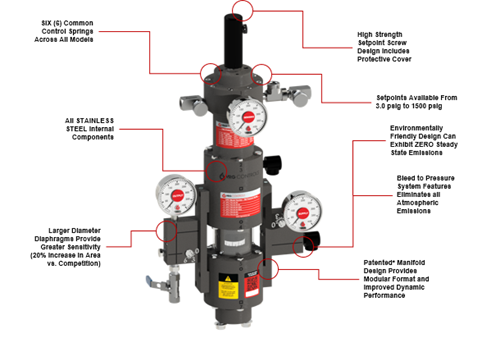

VRG Controls

VRG Valve Pilot Controllers are easily adaptable to most control valves. The modular plug and play design allows for five (5) Valve Pilot Controllers in a single platform providing flexibility in converting from one model to another with ease. Not only does this make maintenance easier; it is also less costly as fewer repair kits are needed.

Work with a Trusted Valve Supplier

Quality engineered solutions and the correct selection of valves for the application are needed to ensure optimal process performance. With 50+ years of experience in energy and industrial applications and a team of knowledgeable valve professionals, Armour Valve is equipped to help you identify solutions that will deliver value to your plant over a long service life. Contact Armour Valve to set up a one-on-one consultation with our team.