Delivering Innovative, Engineered Solutions Through Collaborative Research & Development

Armour Valve is proud to be Conval’s exclusive representative in Canada. Conval is a leader in the severe service market, delivering high-performance valves for the world’s most demanding applications. Conval supplies the industry’s most rugged, in-line repairable valves with the lowest lifecycle cost and continuously designs new and improved solutions to customer valve challenges. Conval’s willingness to collaborate with customers and partners on new solutions has resulted in product enhancements as well as new products that solve specific customer needs. Many of Conval’s existing products that started out as answers to individual customer problems are now in use in diverse applications around the globe.

Conval’s Research & Development Approach

Conval is a dynamic, innovative partner with whom Armour Valve has worked on research and development projects in Canada for more than 20 years. Below are four examples of R&D initiatives that Armour Valve, our customers, and Conval collaborated on and have helped to contribute to safer and more efficient processes in the oil, petrochemical, and fertilizer industries.

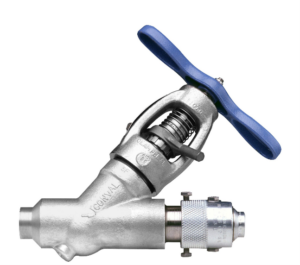

SaVD Series Safe Vent & Drain

In January of 1990, a Western Canada Upgrader was the first major facility in Canada to implement the Conval Clampseal Globe Valve with a HILTAP fitting. This created a safer and more economical means of venting and draining high-pressure systems in comparison to using threaded bull plugs. The unique concept reduced construction capital costs through the elimination of several field welds, while reducing weight and physical size. Operational worker safety improved as bull plugs can be a deadly projectile hazard. The new solution later evolved into what we know today as the Safe Vent & Drain (SaVD) used successfully in many high-pressure, high-temperature projects in Western Canada.

In January of 1990, a Western Canada Upgrader was the first major facility in Canada to implement the Conval Clampseal Globe Valve with a HILTAP fitting. This created a safer and more economical means of venting and draining high-pressure systems in comparison to using threaded bull plugs. The unique concept reduced construction capital costs through the elimination of several field welds, while reducing weight and physical size. Operational worker safety improved as bull plugs can be a deadly projectile hazard. The new solution later evolved into what we know today as the Safe Vent & Drain (SaVD) used successfully in many high-pressure, high-temperature projects in Western Canada.

A collaborative effort to solve a customer’s challenge of reducing the risk to its operators resulted in a breakthrough product to handle double block and bleed applications in a single assembly. The SaVD combines technologies from two companies – HILTAP/OPW and Conval – to allow safe, fast, simple, compact, reliable, and environmentally-friendly depressurizing, venting, and draining of piping systems—all in a single integrated assembly.

Conval Heavy Oil Valve

The idea for the Conval Heavy Oil Valve originated from a site project and valve repair opportunity. Designed specifically for steam service in Canada’s oil sands, the Conval Heavy Oil Valve is a prime example of Conval’s ability and willingness to tailor its designs to meet customers’ special requirements.

The steam produced in this application is heavy with minerals that would crystalize and block the small vent holes on the gland. These minerals would also travel up the stem (chimney effect) and then crystalize on the stem and yoke-bushing threads making the valve difficult to operate. The crystalizing of minerals on the stem threads also added friction when trying to turn the stem which would break the tack welds holding the yoke in place.

In order to address these issues, the following enhancements were made:

- Addition of junk ring in packing of #9 and #10 valves in order to reduce the amount of packing friction

- Enlarged holes in gland to allow packing leaks to come out at the gland instead of going up the stem and into the yoke bushing

- Fully welded yoke bushing in place of tack welding

Clampseal® Fire-Safe Globe Valve

Conval and Armour Valve developed the Conval Clampseal Fire-Safe valve, which is an API 6FA-rated Fire-Safe valve, after inspection of valves that were exposed to a fire and extreme heat at a petrochemical plant. This valve is the only globe valve to pass API 6FA.

Conval and Armour Valve developed the Conval Clampseal Fire-Safe valve, which is an API 6FA-rated Fire-Safe valve, after inspection of valves that were exposed to a fire and extreme heat at a petrochemical plant. This valve is the only globe valve to pass API 6FA.

Fire-safe features include:

- Retrofits with any standard Clampseal Globe Valve

- Single piece packing gland with integral gland wrench (IGW) for easy packing adjustments without special tools

- Cartridge-style packing chamber with a secure, leak-proof bonnet allows rapid access to valve trim for inspection and maintenance

- Pressure seal backseat provides for complete isolation of packing from line pressure when the valve is fully open

Conval Urea Valves

In the early 2010s, Armour Valve started to discuss urea applications with a fertilizer plant experiencing valve performance issues. Their existing valve supplier had challenges securing a Canadian Registration Number (CRN) for new valves, which greatly affected procurement, leaving most plants with the option of repair only. Leveraging Conval’s already strong sourcing, design expertise, and quality program related to specialized material procurement and testing, Armour Valve collaborated with Conval to devise a solution.

In the early 2010s, Armour Valve started to discuss urea applications with a fertilizer plant experiencing valve performance issues. Their existing valve supplier had challenges securing a Canadian Registration Number (CRN) for new valves, which greatly affected procurement, leaving most plants with the option of repair only. Leveraging Conval’s already strong sourcing, design expertise, and quality program related to specialized material procurement and testing, Armour Valve collaborated with Conval to devise a solution.

Conval’s engineering team worked closely with the fertilizer plant and secured CRN approvals for the urea designed globe valves the plant was targeting for purchase. This collaboration resulted in Conval designing a range of in-line repairable valves specifically for urea service with CRNs available for valves and flanges in urea grade material.

Today, Conval has a full portfolio of urea valves that includes Globe, Piston Check & Stop Check in Y-, T- and Angle patterns, Gate Valves, Metal Seated Ball Valves, and In-line / axial Check Valves.

Custom Solutions from Armour Valve & Conval

Armour Valve specializes in helping customers to find solutions to both their everyday and unique valve needs/challenges. We collaborate with our partners to find the right solution for customer application requirements by utilizing our internal application specialists, engineers, and manufacturing partners like Conval to create a custom-engineered solution if needed. Visit our website for more information on our products and partnerships, or contact us to book a consultation to learn more about our valves and process equipment.