Gases, such as oxygen, nitrogen and hydrogen, play a vital role in numerous industries, from chemicals and pharmaceuticals to energy and food and beverage. Ensuring the safe and efficient handling of industrial gases is crucial and valves are indispensable components in gas systems, regulating flow, pressure, and direction. They provide essential control and safety measures, allowing operators to manipulate and isolate gases as needed. With their diverse designs and functionalities, industrial valves help to maintain the integrity and optimal performance of gas handling systems across a wide range of industries.

Industrial Gas Handling

Industrial gas handling can be challenging for valves when the application calls for high pressures, extreme temperatures, or media that causes embrittlement or corrosion. Industrial gas processes often require valves capable of handling large flow rates while maintaining low leakage rates and preventing gas loss, ensuring precise control and reliable isolation.

With the right valve solutions, tailored specifically for industrial gas applications, businesses can optimize their gas handling operations, enhance safety measures, and achieve efficient and reliable performance. Armour Valve is dedicated to supporting our customers by providing a range of solutions that suit their unique application requirements and prevent harm to people and the environment. Our industrial gas solutions include the following:

Goetze Valves

Goetze manufactures safety valves and fittings for cryogenic applications, hydrogen, and other industrial gases for safeguarding, shutting off, controlling or switching systems. Goetze safety valves play a crucial role in ensuring safety in high-pressure refueling processes and in the secure storage of gases in large tanks. Goetze valves have achieved worldwide recognition and are extensively employed in projects involving H2 refueling stations. The company also specializes in manufacturing a comprehensive range of hydrogen safety valves for fuel cell vehicles, production processes, and Hydrogen storage tanks.

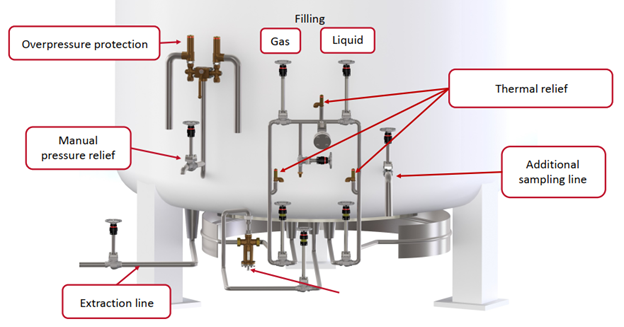

In addition, Goetze offers a comprehensive range of tank protection solutions tailored for cryogenic applications. Below are some notable examples of locations of their cryogenic valves for tank protection.

Goetze fittings on a cryogenic bulk tank

VRG

Experience the cutting-edge technology of VRG Controls, a leading manufacturer of Valve Pilot Controllers (VPC) for hydrogen service that ensure zero steady state emissions control. VRG’s innovative modular plug and play design delivers the convenience of a simple 5 in 1 configuration system while enabling seamless compatibility with both double-acting piston and spring return valve actuators, all within a single platform. The VPC design enables the pressure controller to cycle less, spending more time in a zero-bleed steady state and making it more sensitive and responsive to changing conditions.

VRG Controls Valve Pilot Controllers

VRG also manufactures zero-emission gas pressure regulators that eliminate atmospheric emissions in natural gas, hydrogen, and hydrogen-methane blend applications. Visit our website to learn more about VRG’s solutions and how the company embeds ESG (environment, social, and governance) into their product strategy.

Somas

Made of stainless acid-proof steel, SOMAS Cryogenic Ball Segment Valves are designed for optimal sealing and corrosion resistance. The segment moves out of the flow path, minimizing the risk of clogging and increasing flow capacity. Customizable seats allow users to maintain optimal temperature control, regardless of operating conditions. Seats and stems are replaceable by removing the valve from service and removing the integral seat retainer for easier service and less downtime. Somas also manufactures butterfly valves specifically designed for cryogenic applications and capable of operating at temperatures as low as -196°C.

Boehmer

For more than two decades, Boehmer Ball valves have proven their reliability in hydrogen service, demonstrating excellent performance in both 100% pure hydrogen and hydrogen blends. These valves are manufactured with the fully welded, forged body design that Boehmer is known for. Equipped with a PMSS sealing system, Boehmer ball valves deliver optimal sealing and are currently installed at the ATCO Fort Saskatchewan Hydrogen Blending project in Alberta alongside other hydrogen pipeline projects currently underway in Canada.

Boehmer Valves installed at the ATCO Fort Saskatchewan Blending Project

Conval Cryogenic Valve

Conval Clampseal® Cryogenic Valves are designed for high-pressure, low-temperature applications to -320°F. The valve is in-line serviceable and can be repacked by simply swapping the bonnet chamber with a fresh pre-packed and tested unit. The pressure seal bonnet provides ready access for servicing with no welds to cut or seal rings or gaskets to replace. The solid stellite disc and seat also provide a long operational life in a low temperature environment. High-pressure globe valves suitable for hydrogen production are also available from Conval Valves.

Armour Valve’s Quality Solutions

At Armour Valve, we have established strong partnerships with our principal suppliers and evaluated and approved more than 100 reputable brands for their quality. This extensive network enables us to offer comprehensive assistance in sourcing solutions or developing custom solutions tailored to your specific application requirements. We understand that each customer has unique needs, and our team is dedicated to providing personalized support. Get in touch with us today to schedule a consultation and let us help you find the right solution for your needs.