Problem:

A Canadian oil sands mining and upgrading facility was using globe valves on 8, six-inch injection lines to throttle and control the injection of flocculent to a thickener tank below.

Due to the persistently erosive nature of the line media that would destroy the globe valves involved in flocculent injection every 2-3 months, the facility decided to use lower cost orifice plates for throttling, alongside a gate valve for isolation.

The placement of the drop-down lines at the facility required maintenance personnel to work over a railing in order to access the current valves and proposed orifice plates.

A conventional orifice plate would be difficult to change in this location; it was important to the facility that they source a low-maintenance, quick-changeover solution.

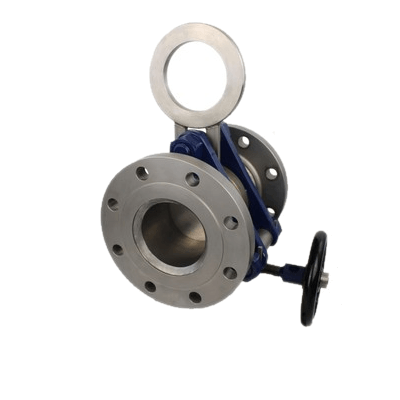

A SchuF/Fetterolf Cam-Set line blind

A SchuF/Fetterolf Cam-Set line blind

The SchuF Cam-Set line blind can be modified to include orifice plates, strainers (shown) or rupture discs. When the in-line addition needs to be replaced the blind can quickly be swung to replace the worn out plate.

The SchuF Cam-Set line blind can be modified to include orifice plates, strainers (shown) or rupture discs. When the in-line addition needs to be replaced the blind can quickly be swung to replace the worn out plate.

Solution

An instrumentation engineer reached out in search of a solution and Armour Valve and SchuF/Fetterolf suggested a SchuF/Fetterolf Cam-Set line blind customized with orifice plates.

While not traditionally used for throttling, a Cam-Set line blind can be equipped with orifice plates on each end of the spectacle plate (Cam-Sets can also be equipped with strainers or rupture discs). As one orifice plate wears out, operators can isolate the line and quickly swing the blind to move the second orifice plate into position. The worn plate can then be replaced in-line.

The time for two maintenance personnel to replace a single conventional orifice plate in the hard-to-reach location was estimated at 60 minutes. A modified SchuF/Fetterolf line blind can be maintained by a single person in as little as 5 minutes.

Impact

SchuF Cam-Set line blinds were installed on all 8 injection lines where they have helped to greatly reduce maintenance time and replacement costs at the facility.

Previously, two maintenance personnel would spend approximately 3 to 4 hours to replace each of the globe valves.

Maintenance of a SchuF/Fetterolf line blind customized with orifice plates can be performed by one person in as little as 5 minutes.

| Throttling Option | Workers | Estimated Service Time Per Worker |

|---|---|---|

| Original Globe Valve | 2 | 24-32 hrs |

| Conventional Orifice Plate | 2 | 8 hrs |

| Modified Cam-set Line Blinds | 1 | <1 hr |