For power producers, maintaining efficiency and reliability is critical. High-pressure and high-temperature environments place intense demands on equipment, particularly the valves responsible for isolating and controlling critical systems. For power plants seeking improved reliability and minimal downtime, Armour Valve’s high-performance solutions offer time- and cost-saving benefits.

With an emphasis on in-line repairable valves with robust designs built for long service life, Armour Valve helps power producers benefit from the lowest total cost of ownership over equipment service life. In this post, we will explore several of Armour Valve’s solutions for power and how they can help you optimize your plant operations.

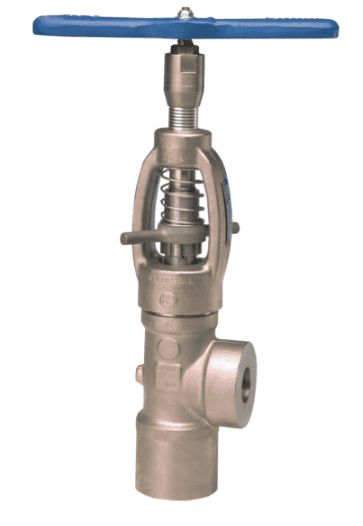

Conval Y-Globe Valve: Reliable Isolation for Critical Service

Power plants require valves that can handle extreme conditions while ensuring safe operation and ease of maintenance. The Conval Clampseal Globe Valve is a vital solution for isolation in high-pressure and high-temperature plant applications, such as vents and drains.

What sets the Conval Y-Globe Valve apart is its in-line repairable design, which reduces downtime and maintenance costs by allowing maintenance teams to repair the valve without cutting it out of line. This feature is particularly useful for power plants aiming to maintain operational efficiency while minimizing costs over the life of the plant. One major power plant that switched to Conval experienced an increase in valve repair success rates from 50% to 90%, leading to significant cost savings and less disruption to operations.

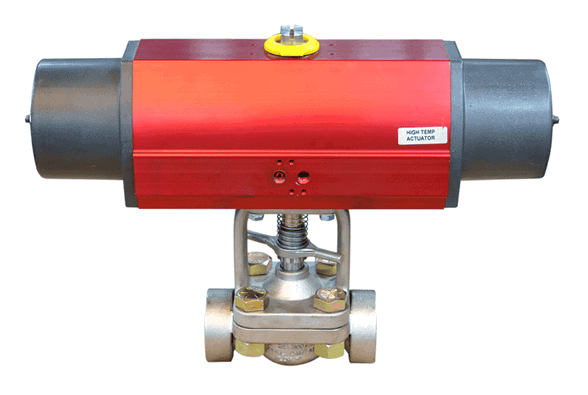

Conval Ball Valve: Quick, Efficient Isolation

The Conval Ball Valve (Camseal) is designed for quick quarter-turn actuation, offering fast and efficient isolation in high-pressure environments. The Camseal Ball Valve is a reliable choice for critical applications, such as air heater steam isolation and attemperator isolation block valves, ensuring dependable performance where it matters most. We’ve found that our customers achieve optimal flow control and extend the service life of critical systems by pairing the Camseal Ball Valve with the Conval Y-Globe Valve for inboard and outboard applications.

Additionally, the Conval Ball Valve features zero leakage and cartridge-style top entry design, making it easily serviceable and an ideal choice for demanding applications. One client, a Canadian combined utility company, contacted Armour Valve to improve the performance of the main steam attemperator block valve. We recommended the Camseal Ball Valve to deliver reliability and efficiency within their operations.

Conval Throttling Valve: Precise Flow Control for Continuous Blowdown

Power plants often require continuous blowdown systems to maintain boiler efficiency and remove impurities. The Throttling Valve is specifically designed for this task, offering precise control over flow rates while ensuring that water or steam flow is finely adjusted based on real-time system needs.

The throttling valve features a pressure-seal bonnet and replaceable seat/venturi, ensuring a long service life while reducing the need for frequent maintenance. We’ve previously applied Conval Throttling Valves to optimize continuous blowdowns in power plants, reducing costs and improving system performance.

For aging heat recovery steam generator (HRSG) plants, Conval also manufactures a Clampseal® Unit Tandem Blowdown Valve for boiler blowdown and

bottom blow-off service. These severe service valves efficiently manage steam or fluid flow under high differential pressure.

Conval’s Unit Tandem Blowdown Valves are easy to maintain and fully serviceable in-line using standard Conval tools and readily available parts. Designed as a seamless drop-in replacement for numerous brands, this solution saves engineering and MRO teams valuable time and reduces expenses. Available in a right-hand seatless design with springs and a left-hand hard seat by hard seat configuration, pressure classes and materials and with various connections.

Actuated Isolation Valve: Automated Protection for Control Systems

We recommend our Conval Globe Valve or Camseal Ball Valve, equipped with an electric or pneumatic actuator to automate isolation functions in high-demand systems. Engineered with the in-line repairable features that our customers have come to rely on from Conval, these actuated isolation valves are crucial for protecting downstream components such as control valves in steam systems, preventing damage from unnecessary leakage or cold-water injection that can cause thermal shock.

By automating the isolation process, these valves help power plants avoid thermal cracking and improve overall system safety. The automated actuation ensures that flow is efficiently controlled, reducing the need for manual intervention and minimizing risks associated with fluctuating demands. You can explore a detailed case study on how we have helped customers prevent significant issues in their steam systems with a simple actuated ball valve solution.

Steam Conditioning Valve: Managing Pressure and Temperature with Precision

One of the most versatile solutions Armour Valve offers is the Hora Steam Conditioning Valve, which combines pressure and temperature reduction within a single unit. This valve is essential in pressure reducing stations, ensuring safe and efficient operation during turbine shutdowns by redirecting steam to condensers. It also plays a critical role in delivering lower-pressure steam for auxiliary systems such as building heating.

By combining the functions of a control valve and desuperheater in a single unit, the Hora steam conditioning valve helps reduce the number of components needed, simplifying the system and improving overall efficiency.

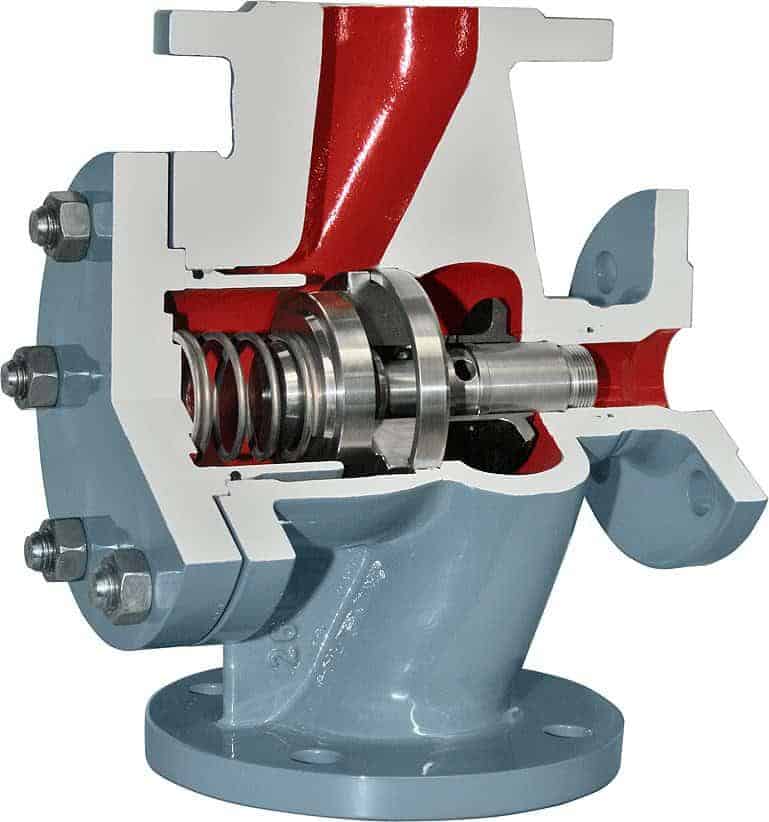

Pump Protection Valve: Preventing Pump Motor Overheating

Pumps are vital to power plant operations and ensuring they don’t overheat is critical. The Pump Protection Valve automatically opens a bypass route when flow demand drops below a critical level, preventing centrifugal pumps from dry running and overheating. This valve is a key component in feedwater systems, where continuous water flow must be maintained to avoid equipment damage.

With its automatic recirculation feature, the pump protection valve ensures that pumps are consistently protected during low-demand periods, reducing the risk of downtime and expensive repairs. Plus, its in-line serviceable design feature makes it easy to repair in-line, reducing maintenance time.

Maximize Power Plant Efficiency with Armour Valve

Armour Valve’s high-performance solutions are designed to tackle specific challenges faced by power plants. From ensuring reliable in-line valve repair to offering innovative flow control solutions, each valve plays a vital role in maintaining system efficiency and safety. By partnering with Armour Valve, power plants can reduce downtime and lower maintenance costs.

We’ve showcased some of our proven power solutions that have successfully optimized customer plant operations. Contact us for a product consultation and we’ll work with you to find the ideal solution tailored to your needs. Don’t let downtime and inefficiencies hold you back—optimize your plant today with Armour Valve.